5 Axis CNC Machining Services

Fast delivery of high-precision 5-axis solutions.

- From 1 to 1,000 parts

- Lead time as fast as 1 day

- Confidentiality Agreement

Our Precision 5-Axis Machining Services

When looking for 5-axis machining services, you cannot compromise on quality if you want to manufacture parts that meet your quality requirements. At Keyanng, the 5-axis CNC machining service is so rigorous that the team of seasoned experts has extensive experience in handling different projects in the best way. Our 5-axis machining services take all the technical aspects of creating prototypes and parts, allowing you to focus on getting your product to market.

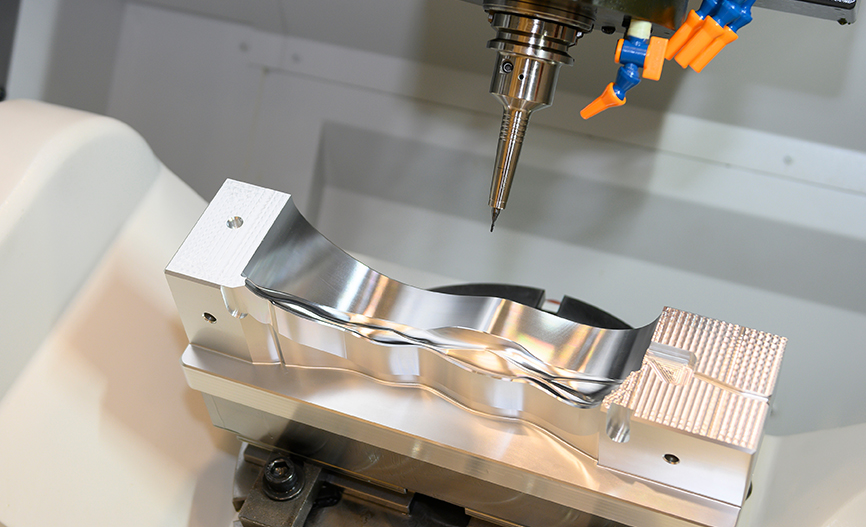

What is 5-axis machining?

Five-axis machining means at least five-coordinate axes (three linear coordinates and two rotary coordinates) on a machine tool. It can be processed simultaneously with coordinated movements under the control of a computer numerical control (CNC) system. Linkage means that the axes of the CNC machine tool reach a certain set point at the same time at a certain speed, and five-axis association means that all five axes can be used.

Five-axis CNC machining is specially used to process complex curved surfaces. It is widely used in aviation, aerospace, military, scientific research, precision instruments, high-precision medical equipment and other industries.

Advantages of

5-axis machining with Keyanng

- Experience

Our engineers have built up rich, deep experience from many previous projects, so they can handle complex and precision parts in several industries without a problem.

- High Quality Guarantee

Keyanng has advanced manufacturing and testing equipment. Quality is assessed at every stage of our preparation, manufacturing and inspection to ensure that the quality of 5-axis CNC machined parts is always up to scratch.

- Quick Turnaround

We return quotes within 24 hours on average, but due to the very high precision level of 5-axis service, parts will be shipped within 15 days (other services only take about 7 days), and we have a 99% on-time delivery and quality rate.

Typical 5-axis machined parts we offer

In our 5-axis machining service work, we found that in addition to traditional aerospace, automotive, ship and other fields (curved surfaces with large curvature), 5-axis machining services are required. Due to functional appearance requirements, daily necessities have also begun to use 5-axis machining services.

Here are some classic 5-axis machining projects:

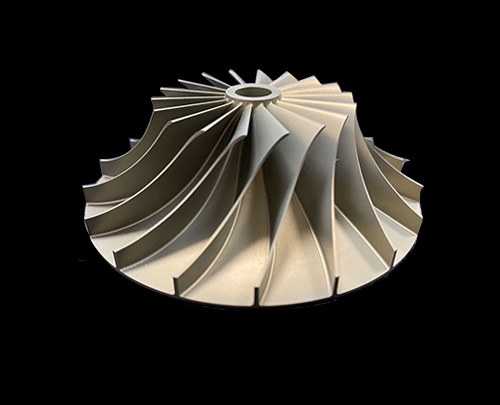

Impeller

Blades are one of the core components of steam turbines, aerospace engines, etc. The blade profile is a space curved surface with complex shape, the root fillet of the blade is composed of a plurality of arcs with variable diameters, and some of the blade bodies also have a damping table in the middle. Complex geometries can only be accomplished by 5-axis machining.

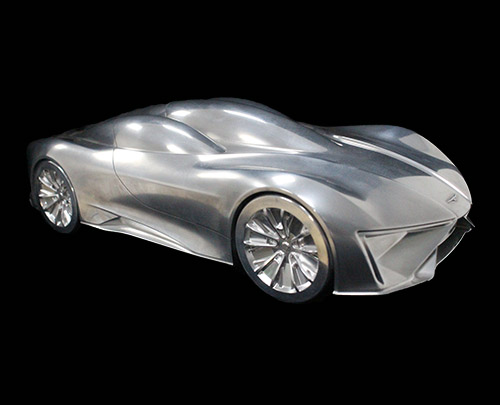

Crafts/Models

5-axis machining is also very suitable for model making because of its perfect detail engraving. Such as car models, architectural models, human body models, etc., and 5-axis machining services are pretty extensive in craft manufacturing.

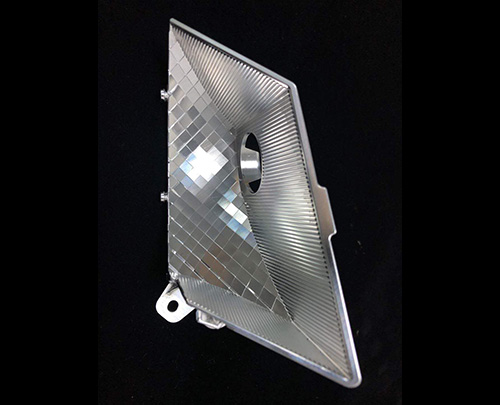

Car Accessories

In addition to mechanical parts such as aluminum hoods and covers, and steel shafts, 5-axis machining also excels in parts with tiny features such as light guides and reflectors.

Advantages of 5-axis machining

Efficiency

In the five-axis machining, the flat bottom end mill is used to maintain a vertical state for the machining surface of the complex mold, which can greatly reduce the machining time.

High precision

Through the five-axis machining technology, the problem that the workpiece needs to be debugged and installed several times at complex angles can be solved, which not only shortens the time, but also greatly reduces the errors generated.

Strong processing ability

Five-axis machining can process complex parts, such as drilling, taper machining, cavity recesses, etc. required for complex surfaces, which cannot be done by traditional methods, but five-axis machining can be easily achieved!

Shorten the development cycle

This is an advantage based on the functionality and efficiency of 5-axis machining, which allows engineers to machine complex parts without developing particularly complex programming. It also helps to shorten the lead time..

Plastic 5-axis machining FAQ

5-axis machining is a mode of CNC machine tool machining. It is developed from traditional 3-axis and 4-axis CNC machine tools and is an important machining method for machining complex parts.

1. Reduce machining time

In the five-axis machining, the flat bottom end mill is used to maintain a vertical state for the machining surface of the complex mold, significantly reducing machining time. The principle of the five-axis machining center is also suitable for side milling with angled surfaces, which can eliminate the rib-like lines caused by the ball end mill’s processing, making the mold’s surface quality more ideal. It also reduces the increase in manual milling and manual work due to cleaning the mold surface.

2. Improve machining accuracy

Through the five-axis machining technology, the problem that the workpiece needs to be debugged and installed several times at complex angles can be solved, which shortens the time and dramatically reduces the errors generated. High costs have also been saved. The machine tool can also process complex parts, such as drilling, taper processing, cavity recesses, etc., required for harsh surfaces, which traditional methods cannot achieve.

3. High production efficiency

The five-axis machining center can effectively reduce the parts’ processing time and additional time. The spindle speed and feed range of the five-axis linkage machining center are significant, allowing the machine tool to perform powerful cutting with a large amount of cutting. The rapid movement, positioning and high-speed cutting of the moving parts of the five-axis linkage machining center reduce the turnaround time between processes of semi-finished products and improves production efficiency.

There’s a wide range of materials that can be used in 5-aixs machining – you can use aluminum brass, copper, steel, titanium, as well as rigid plastics like PPS, PEEK. Contact us to learn more about the material types available when using 5-axis machining technology.

When machining parts, some designers specify using 5-axis machining when machining parts, which is far more than what is needed. This is not an ideal method. If 4-axis machining is effective, choosing 5-axis machining increases manufacturing costs. However, when you do require 5-axis machining of your complex parts, our engineers will carefully evaluate your project and design the most cost-effective way to perform 5-axis machining for your project.

Start your project with a free quote

All information and uploads are secure and confidential.