Rapid

Metal Casting Services

Precision die casting services for custom metal parts and products with fast turnaround times.

- Tolerance down to ± 0.004'' (0.1 mm)

- Aluminum, Magnesium, Zinc & Steel

- ISO 9001:2015 certified manufacture

Our experience in numbers

3000+

companies served

20000+

Unique parts produced

30+

Shipped country

12

Years In Service

Our Precision Die Casting Services

If you have custom metal parts needs, Keyanng is a die casting service manufacturer that can help. Since 2010, we have held our engineering team and equipment to high standards to consistently deliver rugged parts and prototypes. To ensure superior quality, we use a strict die casting process to ensure that your custom requirements are met.

Why use Keyanng for Metal Casting?

- Extensive selections

We provide a wide range of possible material types, surface finish options, tolerances, and manufacturing processes for your die casting parts. Based on your custom needs, we offer you different quotes and manufacturing suggestions so that you can get an individual approach and the most cost-effective solution.

- Powerful plant and equipment

We have established a strong supply network in China to ensure that your castings are manufactured with efficient and fast lead times. In addition, we have a large number of precision CNC machines for post-processing, which can support your customized various die casting projects.

- Strict quality control

We conduct rigorous quality checks at different stages of the manufacturing process: pre-production, in-production, first article inspection and pre-delivery to ensure the highest quality parts are made.

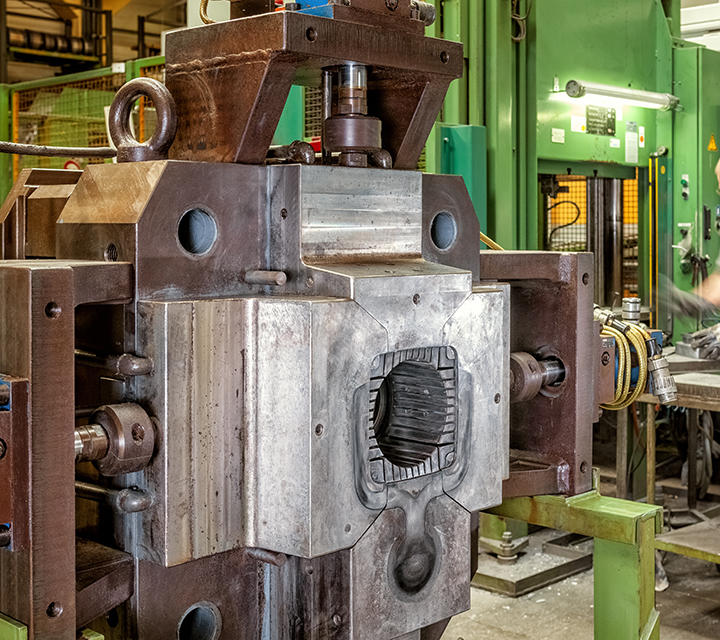

What is Pressure Die Casting?

Die casting is a special casting method with little or no cutting. A precision casting process in which molten metal enters the mold cavity under high pressure and high speed, and is cooled and solidified under high pressure. This is very similar to the process of injection molding. At Keyanng, we form your designs from molten metal (usually zinc, copper, aluminum, magnesium, lead, tin or other tin-based alloys) using certified machines and pressure casting molds. Our die casting process is efficient and very reliable, resulting in significant cost savings.

Hot Chamber Die Casting

Hot chamber die casting is productive and flexible, and is often used to produce small parts, with typical casting cycles of only around 15 minutes. It allows high-volume manufacturing of parts with complex geometries.

The process is suitable for zinc alloys, coal alloys, copper and other low melting point alloys.

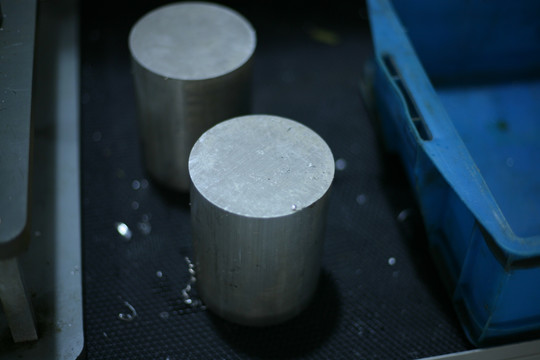

Cold Chamber Die Casting

The cold-chamber die-casting process is developed from the hot-chamber die-casting process. The most notable feature is that it can process metal products with a high melting point, which fills the blank of the die-casting processing range.

It is suitable for metals with high melting points, such as aluminium alloys, pure aluminium, magnesium-aluminium alloys, and copper alloys.

Casting Materials & Finishes

Materials

Aluminum

Zinc

Magnesium

Steel

Lead

Copper

Finishing Options

As Cast

Powder Coating

Bead Blasting

Anodizing

Electro Phoresis

Electroplating

Die Casting Applications

Die casting is one of the fastest metal forming methods, and it is perfect for fast delivery at low cost for high volume manufactured products. Keyanng provides innovative manufacturing solutions for different industrial applications. We supply high-quality parts at competitive prices to customers in the following industries:

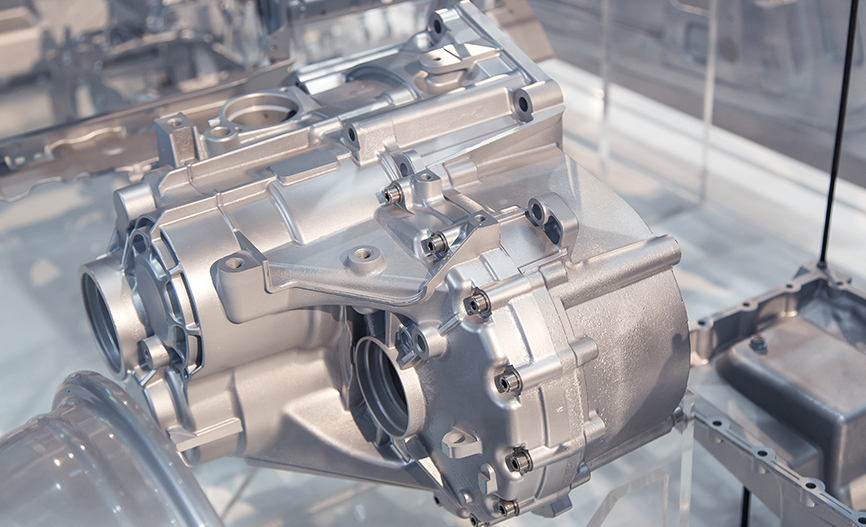

Automotive Parts

This is the type of project we handle the most, such as gears, cylinders, connector housings, transfer cases, small engine parts, and components for other home appliances.

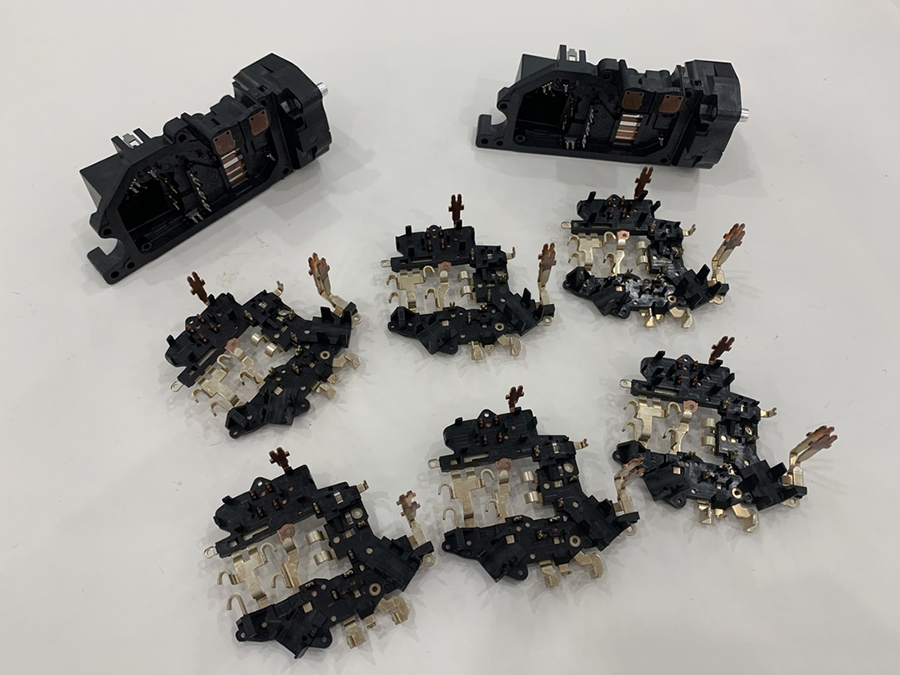

Telecommunication Components

Electrical housings, adapter housings, connector housings, heat sinks and more.

Industrial Accessories

Various adapter housings, adapter housings and other components for electrical systems of industrial appliances and new energy sources.

Commercial Products

This range is very wide, including furniture accessories, bathroom accessories (bathroom), lighting parts and so on.

Plastic Injection Molding FAQ

The cost and fast delivery of the die casting process is more applicable when the project meets the following conditions.

1. Large batches

2. Small and medium-sized parts

3. Simple parts with inner concave

There are 6 steps to producing a die cast product

1. Evaluate whether the project is suitable for die casting process.

2. Mold preparation. Design and manufacture the molds required for the project.

3. Trial production or proofing. In order to ensure the accuracy of the mold and product qualification.

4. Mass production.

5. Trim the casting or machine additional features (such as engravings and small details) on the casting.

6. Surface treatment or other precision machining.

It is worth mentioning that in these 6 steps, we will carry out strict quality checks one by one.

There are numbers of metals and alloys to choose for die casting project. The commonly used metals are zinc, aluminum and magnesium. Also, you can choose copper, brass, tin and lead for custom casting parts, However, it’s hard to determine the best metal because each metal alloy has its unique physical characteristics, advantages and disadvantages. Therefore, if choosing the ideal metal bothers you, a custom die casting parts manufacturer Keyanng can help you.

Indeed, we generally accept orders for metal castings of no less than 1000 units. Because below this value, the cost of metal casting will be much higher than other processes. In any case, we will give a reasonable technical service recommendation according to the project situation.

Start your project with a free quote

All information and uploads are secure and confidential.