Surface Finishing Options

Various options are available to give your metal and plastic parts a high-quality and aesthetically pleasing surface finish.

Surface Finishing

Surface treatment is a process method for artificially forming a surface layer with different mechanical, physical and chemical properties of the substrate on the surface of the substrate. The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product.

Keyanng provides high-quality surface treatment services for all components and parts, regardless of the machining method used in production. We have some skilled specialists who only handle the completion, so the quality of the work done by your product is excellent. If you want the perfect finish for your prototypes and other manufactured components, please contact our customer service team for a fast and accurate quote.

Universal Surface Finishing

Logo & Symbol

There are a number of ways to create logos, symbols and text on prototypes or production parts.

Material All materials

Color Black, any RAL code or Pantone number.

Texture Gloss, semi-gloss, flat, metallic, textured

Types Silk-Screen, Pad Printing, Rub on, Laser Engraving

Painting

Spray painting involves spraying a layer of paint on the surface of the part. Colors can be matched to the customer's choice of Pantone color numbers, while finishes range from matte to glossy to metallic.

Material All materials

Color Black, any RAL code or Pantone number.

Texture Gloss, semi-gloss, flat, metallic, textured

Types Matt, Satin, High Gloss, Texture (spanght & Heavy), Soft Touch( Rubber spanke)

Surface Finishing Of Plastics & Silica gel

Tinted

Tinted is another option to color plastic prototypes besides painting. It is a good solution for turn signal, tail lamp.

Material Silica gel, ABS, PMMA, PS

Color Black, any RAL code or Pantone number.

Texture n/a

Applications Daily necessities, electronic products, toys, mechanical parts

Surface Finishing Of Metal

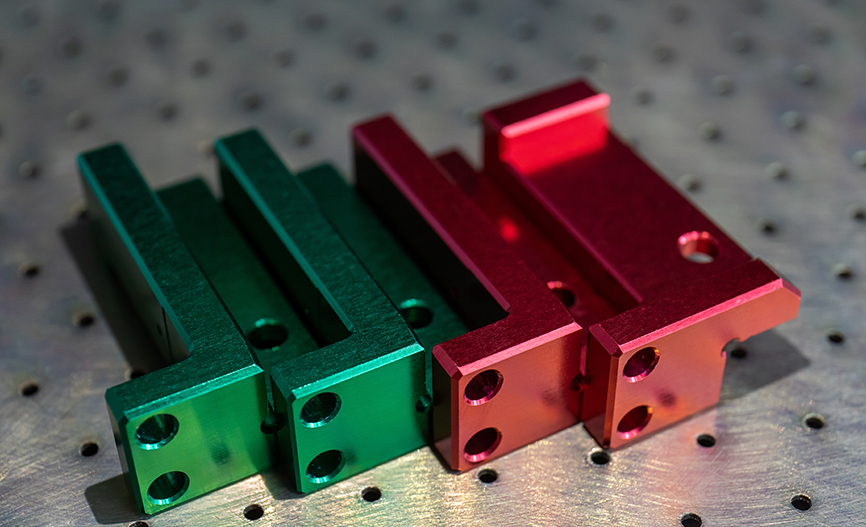

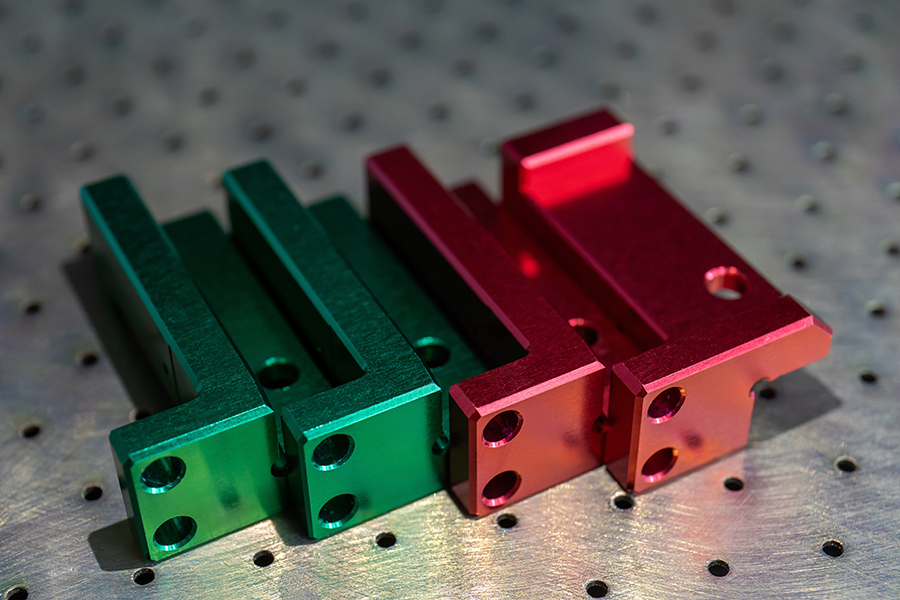

Anodizing

A metal or alloy product is used as an anode, and an oxide film is formed on the surface by electrolysis. Metal oxide films change the surface state and properties, such as surface coloration, improve corrosion resistance, enhance wear resistance and hardness, and protect metal surfaces.

Material Aluminum

Color Clear, black, grey, red, blue, gold

Texture Smooth, matte finish

Thickness 1.8 μm to 25 μm (0.00007″)

Bead blasting

The compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore sand, quartz sand, emery, iron sand, Hainan sand) to the surface of the workpiece to be treated at a high speed. For the purpose of removing surface contaminants, cleaning metal or adding texture, then changing smoothness or surface roughness.

Material ABS, Aluminum, Brass, Stainless Steel, Steel

Color n/a

Texture Matte

Standards Sa1, Sa2, Sa2.5, Sa3

Electroplating

The process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on the electrode. The process can be used for corrosion and wear resistance, as well as for decorative purposes.

Material Aluminum, Steel, Stainless Steel

Texture Smooth, glossy finish

Subtypes Chromed,Metalspanzing,Chrome Sputtering,Color Plating,Zinc Plating,Tinning

Polishing

Polishing is the process of producing a smooth and shiny surface by physically rubbing or chemically disturbing a part. This process produces a smooth surface or specular gloss and is sometimes used to remove gloss (matting).

Material Aluminum, Brass, Stainless Steel, Steel

Color n/a

Texture Glossy

Types Mechanical polishing, chemical polishing

Powder coating

The process of placing functional and decorative finishes (applied as a free-flowing dry powder) uses electrostatic technology and then cures with heat to create a hard finish that is tougher than traditional coatings.

Material Aluminum, Stainless Steel, Steel

Color Black, any RAL code or Pantone number.

Texture Gloss or semi-gloss

Applications Vehicle parts, household appliances, aluminum extrusion

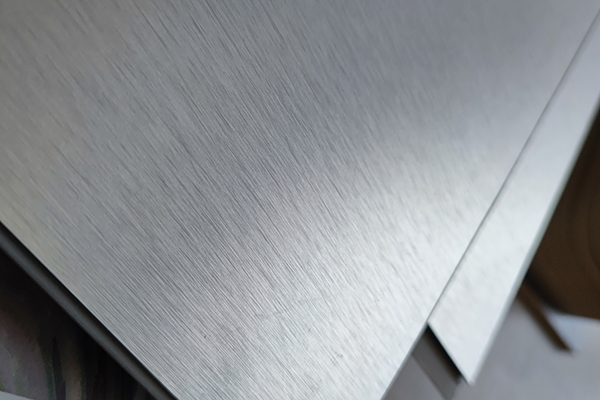

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. Most commonly applied to aluminum.

Material Aluminum, Brass,Stainless Steel, Steel

Color n/a

Texture satin

Standards Sa1, Sa2, Sa2.5, Sa3

Black oxide

This is a method of surface treatment of steel. By reacting the chemical liquid with the material of the workpiece itself to form a black conversion coating, corrosion resistance can be improved and light reflection can be minimized.

Material Steel, Stainless Steel

Color Black

Texture Smooth, matte

Applications Mechanical parts, precision instruments, cylinders, daily necessities

Start your project with a free quote

All information and uploads are secure and confidential.