Welcome to Keyanng's Blog Center

We are happy to share the information, skills and experience we have learned over the years in the non-standard parts manufacturing industry.

Many types of CNC machined parts

Different types of CNC machine tools have other uses. Before choosing CNC machine tools, you should understand their styles, specifications, performance, characteristics, benefits, and application scope to select the most suitable CNC machine tools for machining parts. According to the aspects of CNC machining and many application practices at home and abroad, CNC machine tools are usually most suitable for processing parts with the following characteristics.

What is electroplating? – everything you need to know

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. Improve wear resistance, electrical conductivity, reflectivity, corrosion resistance, and enhance aesthetics. The outer layers of many coins are also electroplated.

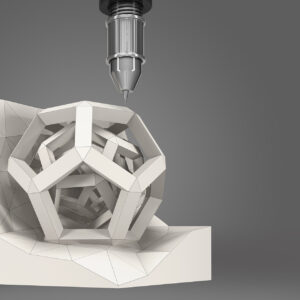

What are the advantages of 3D printing over CNC machine tools?

3D printing has more room to play in the structure of processed parts.3D printing is like building a house, and it has a natural advantage in machining parts with complex structures. For example, hollow parts, as the name suggests, are complex parts with many holes and many grooves. There are also multi-surface, multi-right, beveled parts.

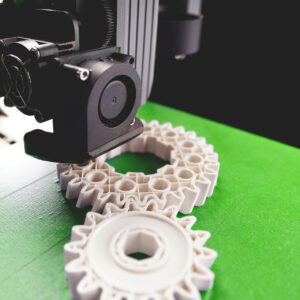

Factors Affecting 3D Printed Part Tolerance and How to Avoid It

3D printing typically builds parts by fusing materials layer by layer to generate the final shape. Manufacturers achieve precise repeatability by adjusting build settings and process parameters. CAD modifications also help improve product results. This article lists 5 factors that affect the tolerance of 3D printed parts and 6 design details suggestions; enjoy reading!

Types of steel used in CNC machining and their uses

The strength and hardness of steel are one of its most sought-after properties. They make steel suitable for construction and transportation applications because it can be used for a long time under heavy and repeated loads. Some steel alloys, the stainless steel varieties, are resistant to corrosion, making them the best choice for parts operating in extreme environments.

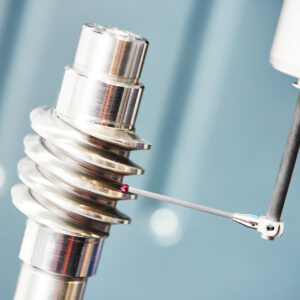

Precision in CNC machining – everything you need to know

Machining accuracy is mainly used to produce products, and machining accuracy and machining error are used to evaluate the geometric parameters of the machined surface. The tolerance level measures the machining accuracy. The smaller the level value is, the higher the precision is; a numerical value represents the machining error, and the larger the numerical value is, the greater the error is. High machining accuracy means minor machining errors and vice versa.