Welcome to Keyanng's Blog Center

We are happy to share the information, skills and experience we have learned over the years in the non-standard parts manufacturing industry.

8 Common Materials for Industrial Robot Parts

Common materials for industrial robot parts can be divided into metal, non-metal, and composite materials, according to the function classification, structural materials, coating materials, control materials, etc. Now let us introduce the common materials one by one. Enjoy reading!

3 criteria for choosing a material for your part

Selecting the material to be used from various materials is a work restricted by many factors. Therefore, how to choose the material of the part is an important part of the part design. The principle of selecting materials for mechanical parts is: that the required materials should meet the requirements of the parts and have good manufacturability and economy.

How are high-precision parts processed?

Precision parts processing produces parts from materials and processes, which are very precise processes. The workpiece processing requirements in precision machining generally require precision machining of parts in the form of numerical control.

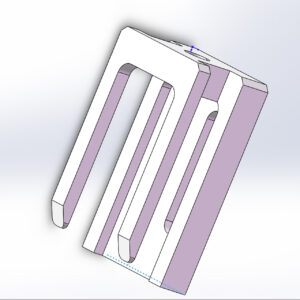

Why do some parts require 3D design drawings?

For parts with complex designs, most manufacturers will ask for 3D files. Compared with 2D plane drawings, 3D drawings can see the appearance and shape of the workpiece; It is best to add some dimensioning and processing requirements to the 3D graphics to form a display form that integrates 3D drawings and process cards; this will enable us to understand your design intent more intuitively and more accurately give appropriate processing plans.

What is aluminum anodizing and its benefits?

Anodizing is an electrolytic process that deposits a chemically stable oxide layer on aluminum surfaces. The resulting oxide film is thicker and stronger than the native oxide coating of aluminum. It is hard, porous, and transparent, making it an integral part of metal surfaces so it will not peel or peel. Once deposited, the oxide film can be coloured in several ways before sealing.