Welcome to Keyanng's Blog Center

We are happy to share the information, skills and experience we have learned over the years in the non-standard parts manufacturing industry.

Advice on how to outsource prototyping to China

We are a prototype manufacturing company with more than 100 employees and 12 years of experience in prototype manufacturing and international trade; we help customers worldwide to realize on-demand manufacturing projects in China. In this article, I’m excited to answer questions about prototype makers in the chapters that follow. Enjoy reading!

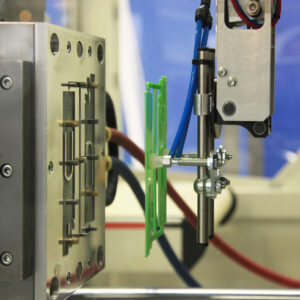

What are SPI Standards: 5 Die Grade Standards

When you need to injection mold complex plastic parts or assemblies, you must understand what SPI standards are. We will discuss a series of questions with you before production to better understand your project needs from multiple perspectives (design, purpose, and goals), which involves an important measure – the SPI standard.

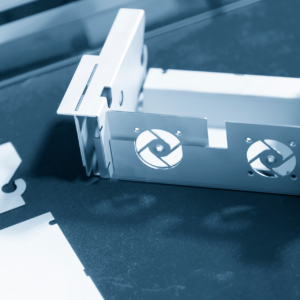

What is sheet metal forming?

Sheet metal is a comprehensive cold working process for thin metal plates (usually below 6mm). Sheet metal parts can be processed by stamping, bending, stretching, and other means and whose thickness is constant during processing.

OEM VS ODM Manufacturing: What’s the Difference?

OEM stands for Original Equipment Manufacturer and ODM stands for Original Design Manufacturer. Below is the meaning and difference between the two terms.

What’s the Difference Between 3-axis, 4-axis & 5-axis Milling?

CNC milling machine is a machine tool that integrates a digital control system on an ordinary milling machine and can perform milling more accurately under the control of program codes. At Keyanng, we have a range of state-of-the-art 3-, 4- and 5-axis milling machines. As a designer, knowing what type of machine your part will be manufactured on is critical to optimizing your design. Let’s read the article and learn the difference between 3-axis, 4-axis, and 5-axis CNC machining!

10 common types of certification for plastic products

Plastic products are widely used in our lives, which means that it is very important to control the quality of plastic products. The most direct method is to carry out testing and certification. In such a wide range of applications, the detection content of plastic products is also different. This article lists 10 common testing items for your better understanding.