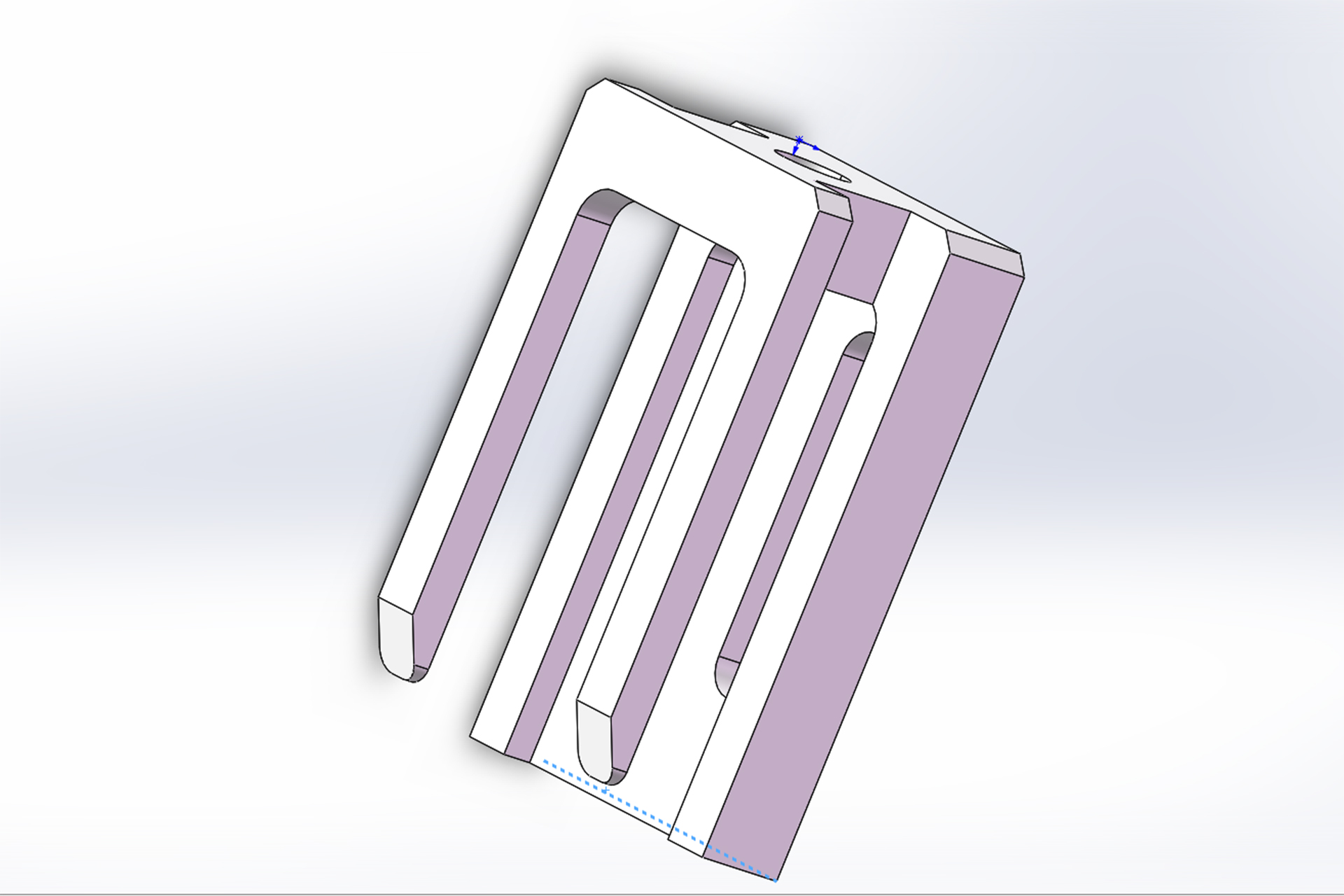

3 criteria for choosing a material for your part

Selecting the material to be used from various materials is a work restricted by many factors. Therefore, how to choose the material of the part is an important part of the part design. The principle of selecting materials for mechanical parts is: that the required materials should meet the requirements of the parts and have good manufacturability and economy.