What is electroplating? – everything you need to know

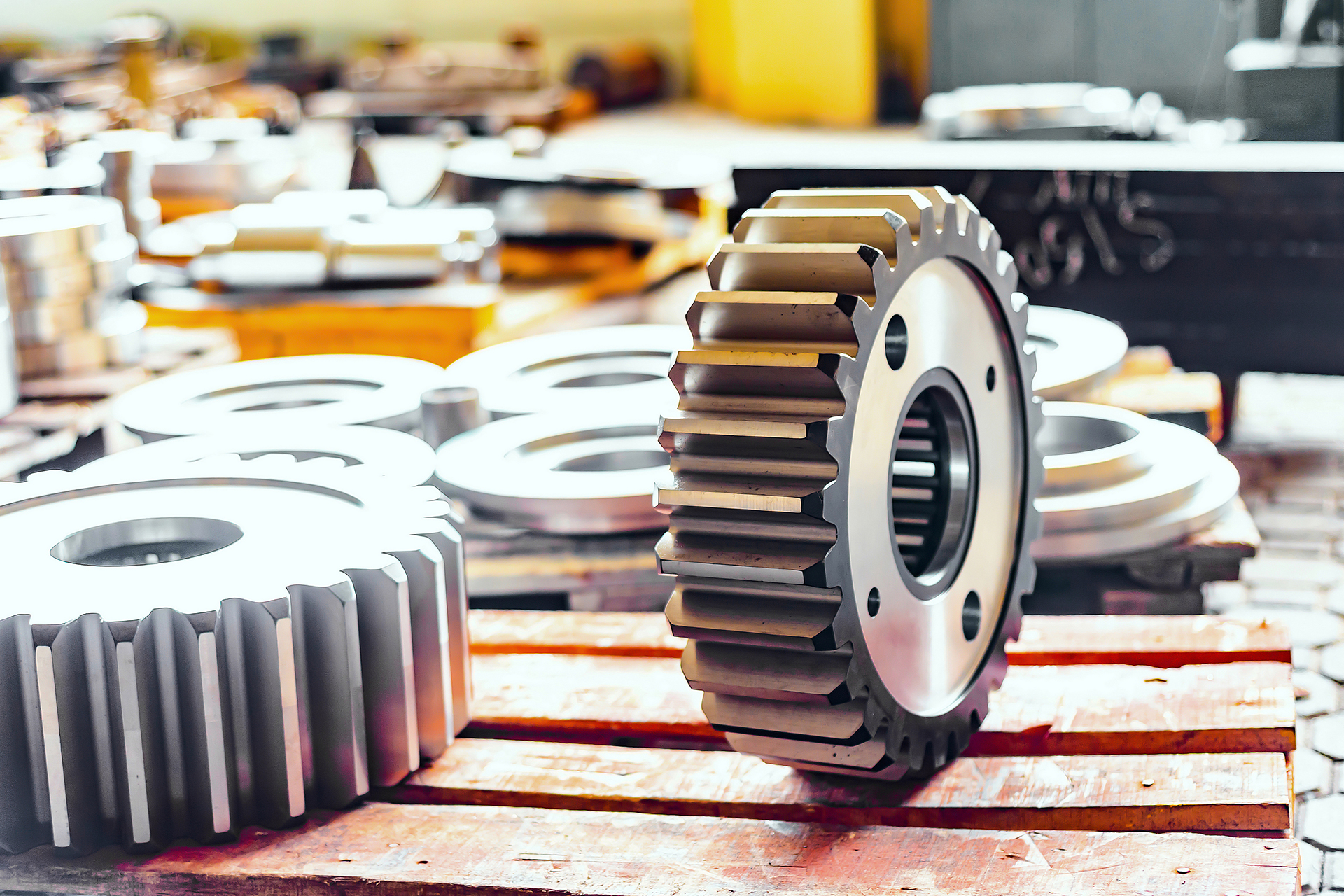

Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. Improve wear resistance, electrical conductivity, reflectivity, corrosion resistance, and enhance aesthetics. The outer layers of many coins are also electroplated.