CNC milling machine is a machine tool that integrates a digital control system on an ordinary milling machine and can perform milling more accurately under the control of program codes. At Keyanng, we have a range of state-of-the-art 3-, 4- and 5-axis milling machines. As a designer, knowing what type of machine your part will be manufactured on is critical to optimizing your design. Let’s read the article and learn the difference between 3-axis, 4-axis, and 5-axis CNC machining!

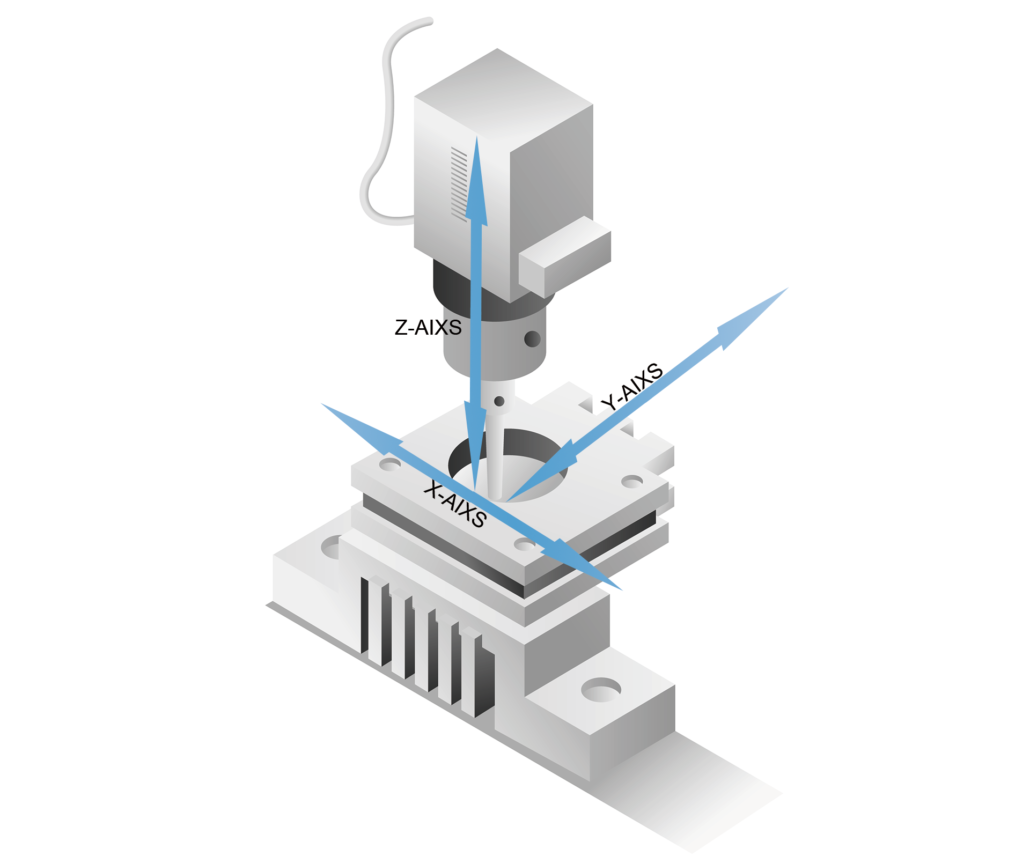

3-axis milling

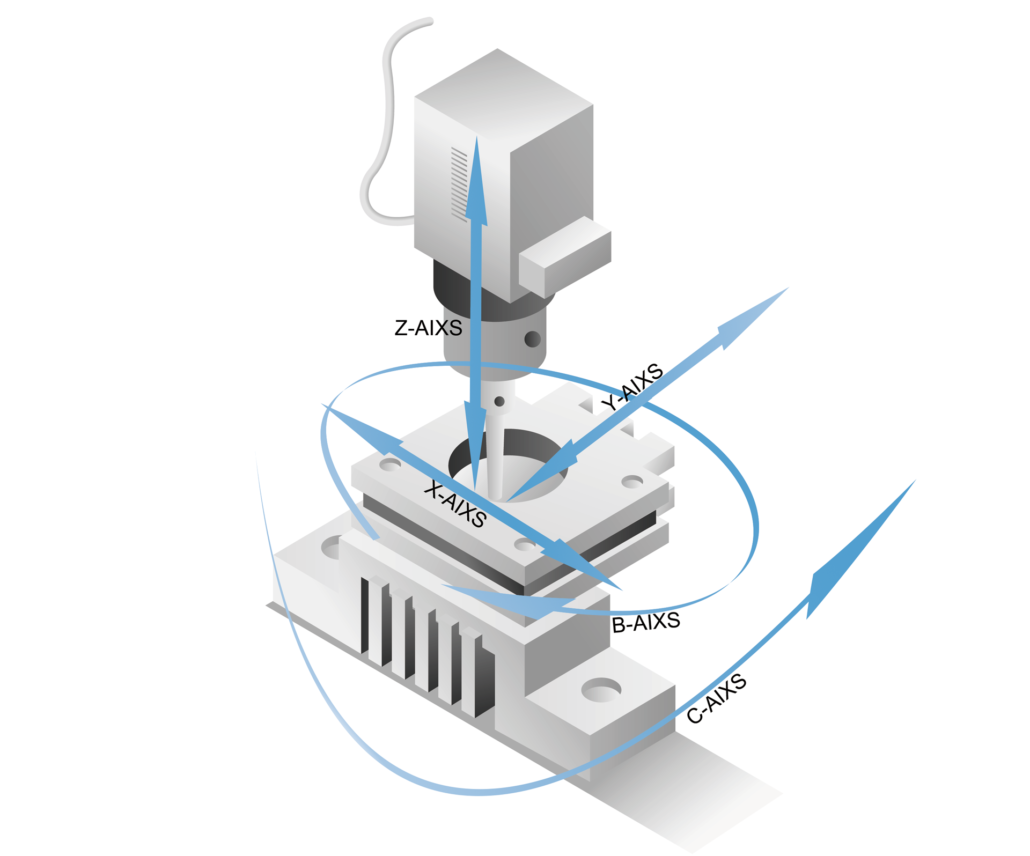

3-axis machining is performed by linear feed axes X, Y, and Z. Three-axis machining is one of the most widely used techniques for manufacturing mechanical parts and can be used for automated/interactive operations, slot milling, drilling, and cutting sharp edges. Because 3-axis machining is only performed on 3 axes, it is relatively simple and can remove material from 3 axes forward, backward, left and right, up and down, and up and down.

The three-axis can only machine one face at a time, which is suitable for machining some disc parts, which is a limitation for many parts that need to machine holes or grooves on multiple faces.

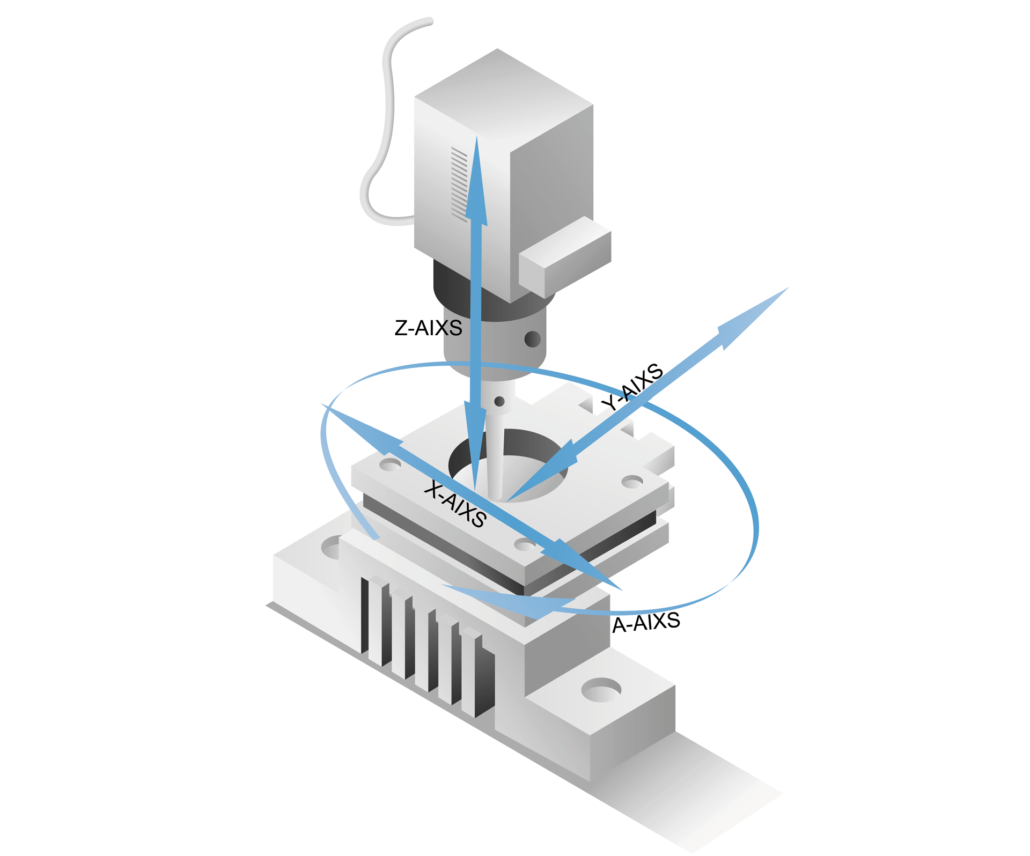

4-axis milling

4-axis CNC machining is to add a rotation axis to the 3-axis, generally 360° rotation on the horizontal plane. But it cannot rotate at high speed, and it is suitable for processing some box parts.

4-axis milling involves the same process as 3-axis machining, where a cutting tool is used to remove material from the workpiece to create the desired shape and contour. However, in four-axis machining, milling is performed on an additional axis. A 4-axis CNC machine operates on the X, Y, and Z axes like a 3-axis machine, including rotation about the X-axis (called the A-axis). This is the 4th axis we added during processing. In most cases, the workpiece will rotate to allow cutting around the B axis.

4-axis CNC machining is the way to go if you need to drill holes on the side of a part of the surface of a cylinder. It dramatically speeds up the machining process and has high machining accuracy.

5-axis milling

5-axis milling is an additional rotation axis on top of the 4-axis. Generally, the vertical surface rotates 360°, and the five-axis can already be fully processed, which can realize one-time clamping, reduce the cost of clamping and reduce product scratches and bumps.

5-axis machining includes all axes for 4-axis machining, plus an additional axis of rotation. Five-axis milling machines are the best CNC milling machines available today. The 5th axis in a 5-axis milling machine revolves around the B-axis, which rotates around the Y-axis in the XYZ plane. This multi-dimensional rotation and tool motion gives the B-axis unmatched accuracy, smoothness, and speed in workpiece production. 5-axis machining can produce very complex parts, so it is so vital in advanced applications such as aerospace applications.

Five-axis machining is also becoming more popular as it offers the option of single-step machining (reduces lead time). It provides better part geometry and improves tool life and ideal cutting positions through tilting the table and machining efficiency.

Due to the high versatility of 5-axis CNC machining, it can be used to manufacture complex precision parts. Such as medical parts for artificial limbs or bones, aerospace parts, titanium parts, oil and gas machinery parts, military products, etc.

Although 5-axis has outstanding advantages over 4-axis and 3-axis, not all products are suitable for 5-axis machining. For example, parts ideal for 3-axis machining are not necessarily ideal for 5-axis machining. If a product that can be machined with 3-axis is processed with 5-axis, it will not only increase the cost but also the effect will not necessarily be better.

Keyanng CNC Milling Services

Keyanng’s professional CNC engineers can manufacture precision CNC machine parts for you to your exact specifications. We machine parts for various industries—whether you’re looking for a specific CNC machined part for a medical clinic or an aircraft part for an aerospace company. We use the most suitable CNC milling service to manufacture your parts instead of the most expensive; submit your project for a free review, and you will receive our quote within 12 hours.