CNC milling

metal and plastic parts

Manufacturer of high precision CNC milling parts from China. Dedicated rapid prototyping and low-volume manufacturing services.

- Confidentiality Agreement

- 200+ material types

- Professional technical support

- From 1 to 1000+ parts

Our CNC Milling Services

We provide CNC milling services for any custom CNC part, whether complex or straightforward, plastic or metal. With our precision 3-axis, 4-axis and 5-axis CNC milling centres, combined with other advanced capabilities and our experienced team, we can provide high-quality CNC parts with fast delivery. We guarantee that your CNC milling project will be handled smoothly by our in-house CNC department and supplier network, meaning your team can focus on getting your product to market. If you are looking for a reliable CNC milling company, Keyanng will not let you down!

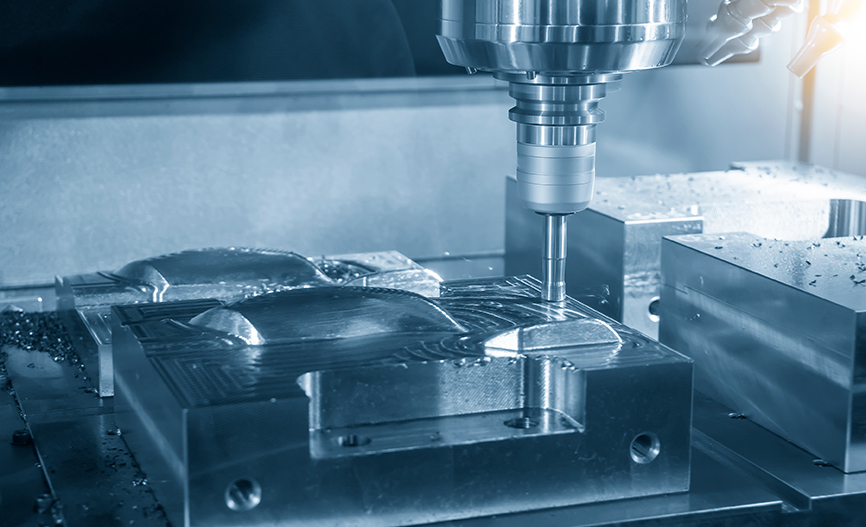

CNC milling is the most common CNC machining process. After the workpiece is properly positioned, material is removed from the workpiece by rotating and moving the tool. The movement of the tool is controlled by computer instructions with extreme precision and repeatability.

The milling cutter can be placed horizontally or vertically, but since CNC machines have 3-axis, 4-axis, and 5-axis differences, this video shows a 4-axis CNC milling machine.

Learn about our 5-axis machining services

Advantages of

Injection Molding with Keyanng

There are a large number of precision machining suppliers. Why choose us? Here’s what we’re most proud of:

- Experience

Our engineers have built up rich, deep experience from many previous projects, so they can handle complex and precision parts in several industries without a problem.

- Advanced Equipment

Keyanng has extensive in-house manufacturing and testing facilities. Your parts will be manufactured and inspected using our state-of-the-art in-house equipment, including precision CNC milling, CNC turning, EDM and LEAD CMM.

- Reliable quality

We return quotes within 12 hours on average, ship in 7 days or less, and we have a 99% on-time delivery and quality rate.

Check out what they

have to say about keyanng

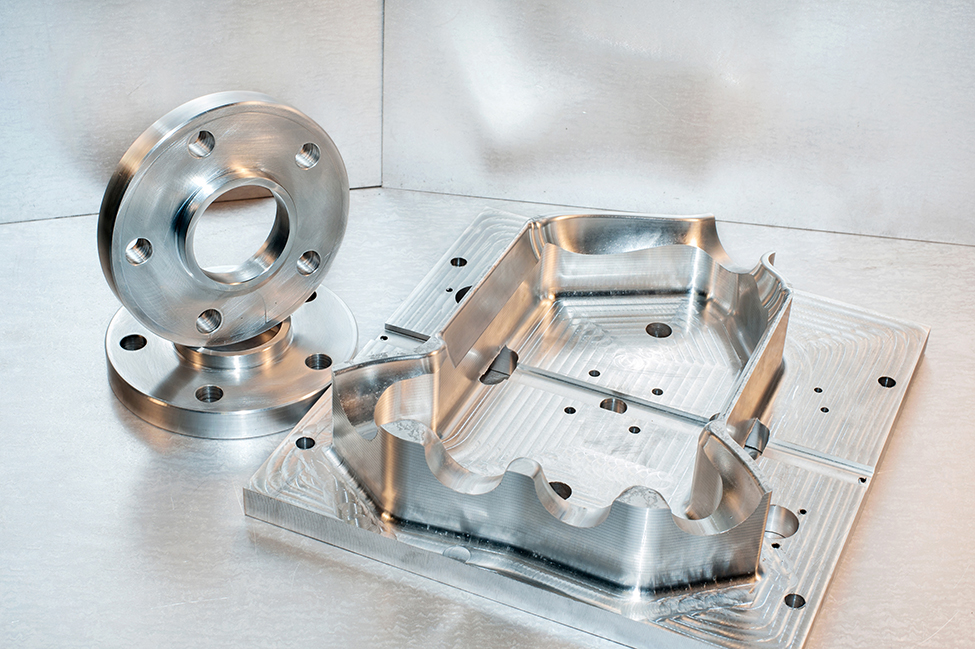

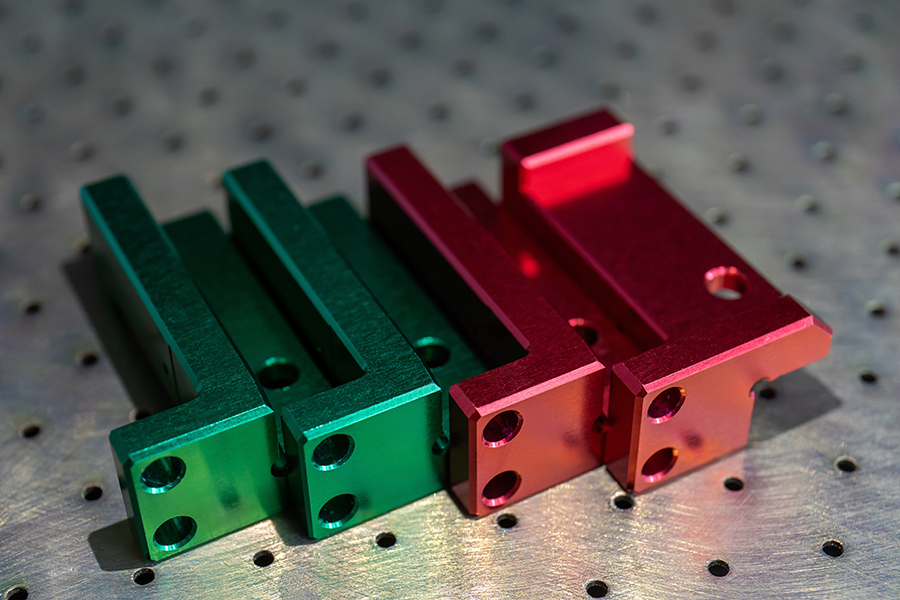

Materials for CNC Milling Parts

Aluminium is an important industrial material and a standard CNC machined material because of its interesting thermal properties and excellent machinability,

making it the material of choice for most manufacturing sectors across a wide range of industries.

A wide range of aluminium processing:

Aluminium 6061, Aluminum 2024, Aluminum 5052, Aluminum 6063, Aluminum 7050, Aluminum 7075, Aluminum MIC-6

Surface treatment:

Sandblasting shot blasting, polishing, anodizing, oxidation, electrophoresis, chroming, powder coating and painting

Custom colours:

Black, natural, blue, green and different colours as your requirement

Various aluminium CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Aluminium CNC machining applications:

Aluminium CNC parts can be used in automotive, electrical, military, medical, aircraft, power generation, aerospace and industrial engineering

Steel is the backbone material for general engineering and industrial applications and is widely used in CNC machining, especially low and

medium carbon steels. Steel is an alloy of iron and carbon and usually contains many other elements such as manganese, silicon, phosphorus, and oxygen.

The carbon content in steel increases its strength and fracture resistance.

Choice of steel models:

4130 steel, 4140 steel, 1018 steel, A36 steel, etc

Surface treatment:

Painting, blackening, chrome plating, nickel plating, nitriding, film, anodizing

Custom colors:

Black, natural, blue, green and different colors as your requirement

Various aluminum CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Steel CNC machining applications:

Automotive, Automation, Robotics, Medical, Aircraft, Power Generation, Mechanical and Industrial Engineering

Stainless steel has good corrosion resistance and high hardness. Due to its excellent physical properties, stainless steel is one of

the most popular industrial alloys for many CNC machining projects.

Wide range of CNC stainless steel materials:

Stainless Steel 15-5, Stainless Steel 17-4, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 420.

Surface treatment:

Sandblasting shot blasting, polishing, anodizing, oxidation, electrophoresis, chroming, powder coating and painting

Custom colors:

Black, natural, blue, green, and different colors as your requirement

Various stainless steel CNC machining processes:

CNC stainless steel milling, CNC stainless steel turning, CNC stainless steel drilling, CNC stainless steel threading

Stainless steel CNC machining applications:

Electronic parts, marine parts, medical equipment, hospital and laboratory instruments, auto parts, pressure tanks, engine parts, welding ferrules, cables, handles, etc.

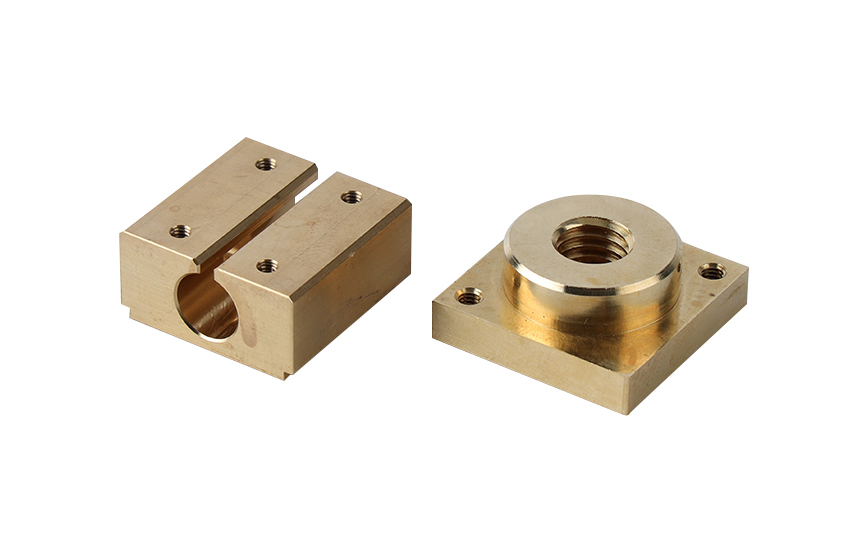

Brass is an alloy made of copper and zinc with strong wear resistance, low coefficient of friction, low melting point, good flexibility and high corrosion resistance,

making it ideal for thermal machinery and products.

Wide range of CNC brass materials:

Copper H62-Copper H96,Copper H177-2,Copper H177-2A,Copper HMn58-2

Surface treatment:

Chrome plating, brushed nickel, antique copper, imitation red copper

Various Brass CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Brass CNC machining applications:

Electrical appliances, electronics, lighting, architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, military supplies

Titanium is resistant to corrosion, chemicals, and extreme temperatures, and has an excellent strength-to-weight ratio. It is a typical ideal material for aerospace,

medical, military, chemical processing, marine industry, and extremely high-temperature applications.

A wide range of titanium processing:

TA1,TA2,TA5,TA22,TA23,TA24,TA31

Various titanium CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Titanium CNC machining applications:

Chemical, Petroleum Industry, Automotive Industry, Medical, Communication, Aerospace

Plastics are an integral part of our daily lives. It is known for its lightweight, high strength-to-weight ratio, electrical insulation,

low price, and suitability for mass production.

Wide range of CNC plastic materials:

● ABS ● PTFE

● Nylon ● PC

● POM ● HDPE

● PEEK ● PVC

● Acrylic ● PMMA

● PET ● PP

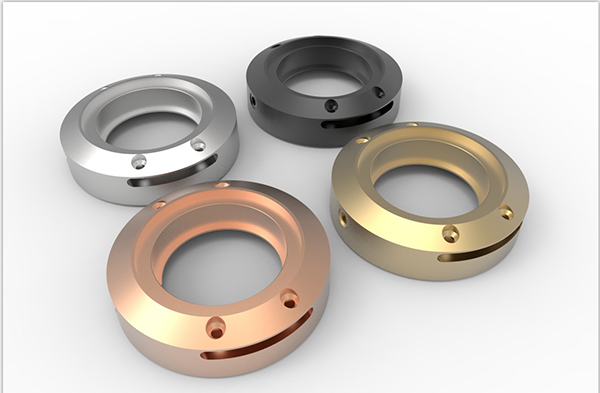

Surface Finishes for CNC Milling Parts

Through electrolytic passivation, a thin layer of aluminum oxide is formed on the outside of

Through electrolytic passivation, a thin layer of aluminum oxide is formed on the outside of

aluminum CNC machined parts, which improves corrosion resistance,enhances wear resistance

and hardness to increase the thickness of the natural oxide layer and protect the metal.

material:Aluminium

Custom colours:Silver (Aluminum), Black, Gray, Red, Blue, Gold.

Texture: Mirror or matte finish.

Thickness: 2-15 microns

Shot peening directs abrasive onto the surface of a part to remove surface contamination, clean metal or add texture, thereby altering smoothness or surface roughness.

Shot peening directs abrasive onto the surface of a part to remove surface contamination, clean metal or add texture, thereby altering smoothness or surface roughness.

Material:Stainless Steel, Aluminum, Titanium, Magnesium

Custom colours:N/A

Texture: matte finish

Processing standard: Sa1、Sa2、Sa2.5、Sa3

In the salt solution containing the pre-plating metal, through electrolysis, the cations of the pre-plating metal

In the salt solution containing the pre-plating metal, through electrolysis, the cations of the pre-plating metal

in the bath are deposited on the surface of the base metal to form a surface processing method of the coating

Material: Aluminum, Steel, Stainless Steel

Texture: Glossy, glossy mirror finish

Type: ·Chrome Plated, Copper Plated, Cadmium Plated, Tin Plated, Zinc Plated

Improve the appearance of new or used metal parts by rubbing or chemically producing a smooth, glossy surface on the part.

Improve the appearance of new or used metal parts by rubbing or chemically producing a smooth, glossy surface on the part.

Material : Aluminum, Brass, Stainless Steel, Steel

Color: not applicable

Texture: Smooth, glossy finish

Placing functional and decorative finishes (applied as a free-flowing dry powder) uses electrostatic technology. It then cures under heat to create a tougher hard finish than traditional coatings.

Placing functional and decorative finishes (applied as a free-flowing dry powder) uses electrostatic technology. It then cures under heat to create a tougher hard finish than traditional coatings.

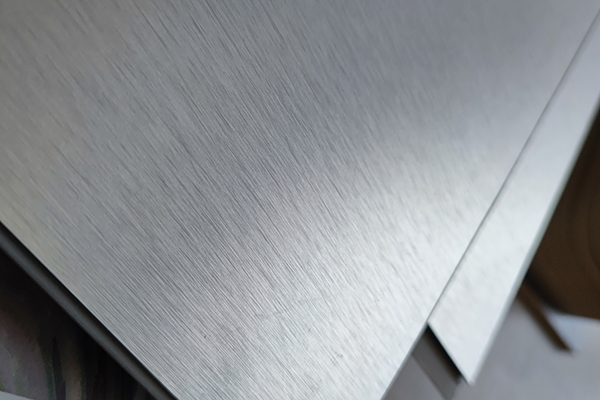

A method of reciprocating and rubbing the surface of the workpiece with the reciprocating motion of the wire drawing cloth to improve the surface finish of the workpiece. The surface texture is linear. Surface quality can be improved, usually for aesthetic purposes.

A method of reciprocating and rubbing the surface of the workpiece with the reciprocating motion of the wire drawing cloth to improve the surface finish of the workpiece. The surface texture is linear. Surface quality can be improved, usually for aesthetic purposes.

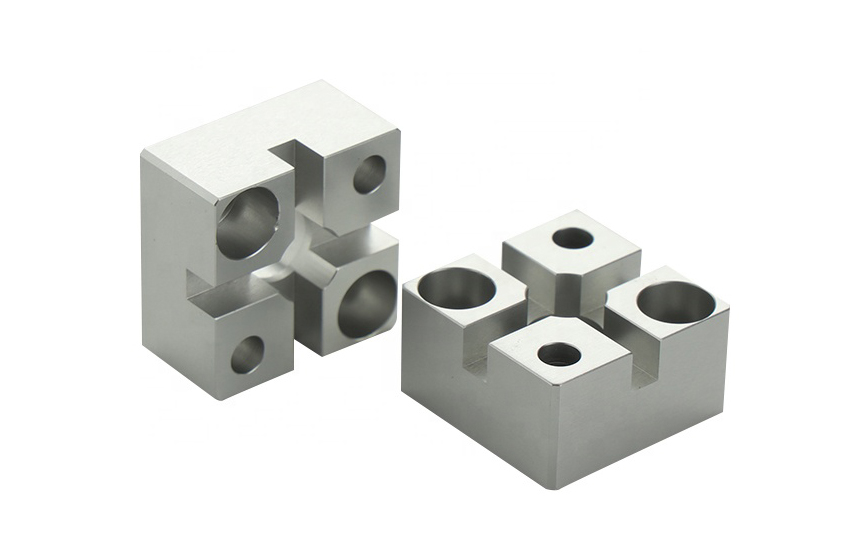

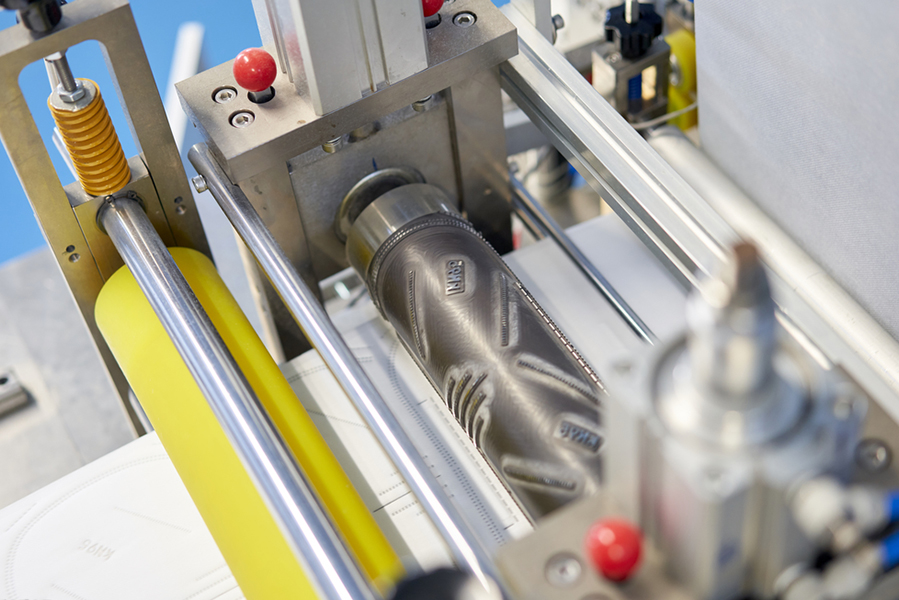

Typical CNC Milling Parts That We Offer

CNC milling is a very flexible way to create prototypes or manufacture large quantities of end-use parts. And there’s a wide range of milling materials to choose from, so it’s suitable for most projects. Our CNC experts know how to cut parts quickly to keep costs down and mill custom-designed parts with complex geometries and tight tolerances in different materials. We have delivered tens of thousands of high-quality CNC parts to customers worldwide.

Machine Components

This is a rotary cutting machine for N95 mask machine. Its function on the machine is to press the multi-layer fabric bonding and shape the mask.

This is our most typical processing project, not just the mask machine, we have manufactured machine parts for 1500+ customers so far.

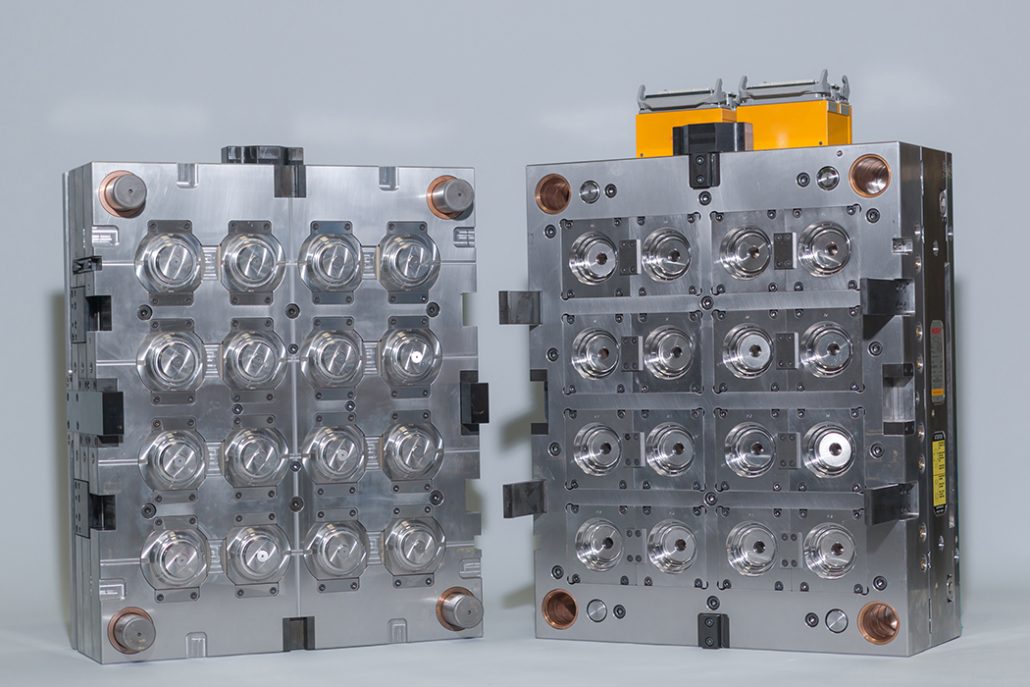

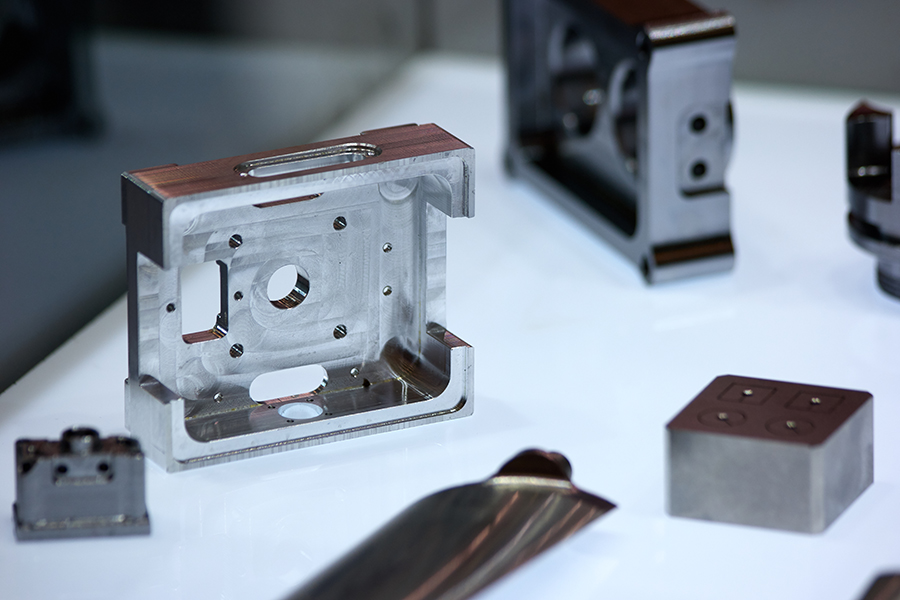

Mold Components

CNC milling plays an important role in mold making. Cavities, mold bases, slides, tappets and other mold components can be milled. Our injection molds are made with a CNC milling process, which allows the mold to maintain consistent precision and surface finish.

Automotive Prototype

Interior panels, molds, drivetrains, pistons, camshafts, turbochargers, aluminum wheels, starter motors, cylinder heads, driveshafts, transmissions, custom parts, and prototype applications—all of which require CNC milling

Medical Parts

Accessories for handheld devices, anatomical models, teaching aids, electronics, ultrasound equipment, physiotherapy equipment, and we are familiar with fracture plates and other parts that can be used in surgery.

Food Industry Parts

Food processing machines and components for cooking, packaging, preparing, storing and handling food.

Electrical Accessories

Electronic hardware, enclosures, metal slats, panels, thin wires, engraved parts and other CNC machined electronic components

Overview: What is CNC milling?

CNC milling is the most common CNC machining process. The material is removed from the workpiece by rotating and moving the tool. The device’s movement is controlled by computer instructions with extreme precision and repeatability.

Milling is different from CNC turning. CNC turning is another standard CNC service. The workpiece rotates, the tool moves in a straight line or a curve, and the tooltip moves relative to the workpiece while removing a certain amount of workpiece material. Get final custom CNC turned parts with desired specifications. Unlike milling, CNC turning is often used to create circular or tubular shapes.

CNC milling can be used for complex contour shapes, Parts that require high precision.

1. First, carry out process analysis according to the part processing drawing, and determine the processing plan, process parameters, and displacement data.

2. Use the specified program code and format rules to write the part processing program list, or use the automatic programming software for CAD/CAM work to generate the part processing program file directly.

3. The content of the processing program is entirely recorded on the information medium (such as punched tape or magnetic tape) in the form of code.

4. The code on the information medium is converted into an electrical signal by the reader and sent to the numerical control device. Programs written by hand can be input through the operation panel of the CNC machine; programs generated by the programming software are directly transmitted to the CNC unit (MCU) of the CNC machine through the serial communication interface of the computer.

5. After the numerical control device performs a series of processing on the received signals, the processing results are sent to the servo system to execute commands in the form of pulse signals.

6. After the servo system receives the executed information command, it immediately drives the milling machine feed mechanism to move in strict accordance with the requirements of the order so that the milling machine can automatically complete the processing of the corresponding parts.

Its number of axes usually defines a CNC milling machine. More axes mean they can move their tools and workpieces in more ways, providing greater cutting flexibility and the ability to manufacture more complex parts in less time.

3 Axis: Standard CNC mills have three axes that allow the spindle (and attached tool) to move along the X, Y, and Z axes. If the cutting tool cannot reach an area of the part, the part must be removed and rotated manually.

4-axis: Some CNC mills add an extra degree of motion by rotating vertically. This allows for greater flexibility and the ability to create more complex parts.

5-axis: The most advanced type of CNC milling machine in widespread use is the 5-axis milling machine, which incorporates two additional angles of motion, usually by increasing the rotation of the table and spindle. Parts often don’t need multiple setups because the milling machine can manipulate them to different positions.

Start your project with a free quote

All information and uploads are secure and confidential.