Custom

CNC turning Service

Manufacturer of high precision CNC turning parts from China. Dedicated rapid prototyping and low-volume manufacturing services.

- Fastest 1 day delivery

- 200+ material types

- From 1 to 1000+ parts

- Confidentiality Agreement

Rapid CNC Turning Service

Keyanng is an experienced precision CNC turning service provider in China with more than 50 CNC lathes and CNC turning centers, providing cost-effective precision machining services with short lead times. Our state-of-the-art CNC turning centers often work with a wide variety of materials, including copper, brass, stainless steel, carbon steel, aluminum and titanium. We can always select the right precision turning process to meet your requirements.

Our CNC Turning Services

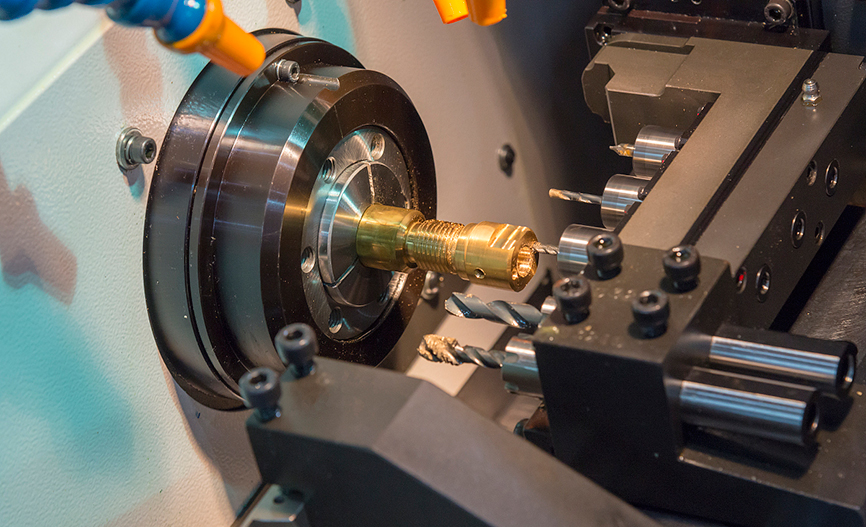

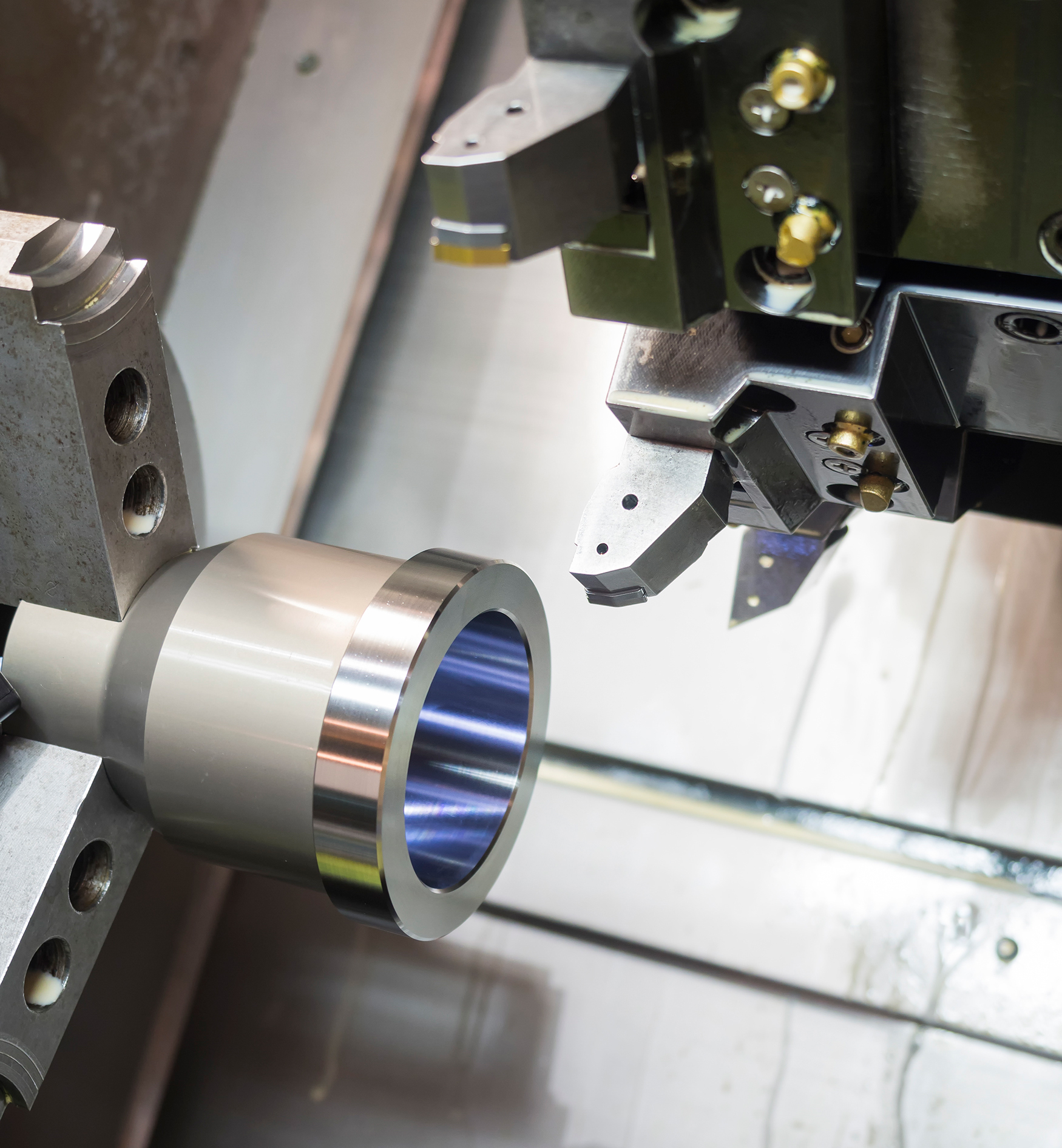

This video shows us the process of CNC turning, which is a common precision CNC machining process.

During CNC turning, the workpiece performs rotary motion, the tool performs linear or curvilinear motion, and while the tool tip moves relative to the workpiece, a certain amount of workpiece material is removed. to obtain final custom CNC turned parts with desired specifications.

We provide CNC turning services for any type of custom CNC part, whether simple or complex, plastic or metal. With our precision CNC turning centers, combined with other advanced capabilities and our experienced team, we can provide high quality CNC parts with fast delivery!

Advantages of CNC turning

- Cylindrical parts

CNC turning machines are ideal for creating round or cylindrical parts. Lathes create these parts quickly, accurately and with excellent repeatability.

- Range of processes

Although generally used for parts of a certain shape, CNC turning can still be used to carry out a variety of cuts, including drilling, boring, threading and knurling.

- One-stop service

We have a variety of CNC fabrication and other process capabilities to meet every need, see our services page.

Our

Quality Commitment

- ISO 9001:2015

- Worldwide shipping within 10 days

- Confidentiality Agreement

- Material certification

- Full dimension report

- Quality Assurance and Refund Policy

Materials for CNC Turning Parts

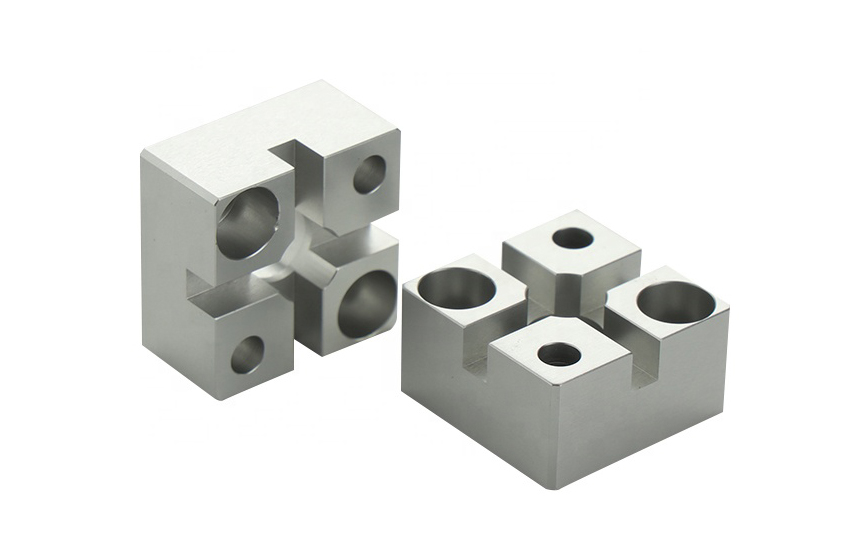

Aluminium is an important industrial material and a standard CNC machined material because of its interesting thermal properties and excellent machinability,

making it the material of choice for most manufacturing sectors across a wide range of industries.

A wide range of aluminium processing:

Aluminium 6061, Aluminum 2024, Aluminum 5052, Aluminum 6063, Aluminum 7050, Aluminum 7075, Aluminum MIC-6

Surface treatment:

Sandblasting shot blasting, polishing, anodizing, oxidation, electrophoresis, chroming, powder coating and painting

Custom colours:

Black, natural, blue, green and different colours as your requirement

Various aluminium CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Aluminium CNC machining applications:

Aluminium CNC parts can be used in automotive, electrical, military, medical, aircraft, power generation, aerospace and industrial engineering

Steel is the backbone material for general engineering and industrial applications and is widely used in CNC machining, especially low and

medium carbon steels. Steel is an alloy of iron and carbon and usually contains many other elements such as manganese, silicon, phosphorus, and oxygen.

The carbon content in steel increases its strength and fracture resistance.

Choice of steel models:

4130 steel, 4140 steel, 1018 steel, A36 steel, etc

Surface treatment:

Painting, blackening, chrome plating, nickel plating, nitriding, film, anodizing

Custom colors:

Black, natural, blue, green and different colors as your requirement

Various aluminum CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Steel CNC machining applications:

Automotive, Automation, Robotics, Medical, Aircraft, Power Generation, Mechanical and Industrial Engineering

Stainless steel has good corrosion resistance and high hardness. Due to its excellent physical properties, stainless steel is one of

the most popular industrial alloys for many CNC machining projects.

Wide range of CNC stainless steel materials:

Stainless Steel 15-5, Stainless Steel 17-4, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 420.

Surface treatment:

Sandblasting shot blasting, polishing, anodizing, oxidation, electrophoresis, chroming, powder coating and painting

Custom colors:

Black, natural, blue, green, and different colors as your requirement

Various stainless steel CNC machining processes:

CNC stainless steel milling, CNC stainless steel turning, CNC stainless steel drilling, CNC stainless steel threading

Stainless steel CNC machining applications:

Electronic parts, marine parts, medical equipment, hospital and laboratory instruments, auto parts, pressure tanks, engine parts, welding ferrules, cables, handles, etc.

Red copper is pure copper, also known as red copper. It has good electrical and thermal conductivity,

excellent plasticity, and is easy to be processed by hot pressing and cold pressing.

Commonly used copper types:

Copper T1、CopperT2、CopperT3、CopperTU1、CopperTU2

Various Copper CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Copper CNC machining applications:

Electrical industry parts, electronic parts.

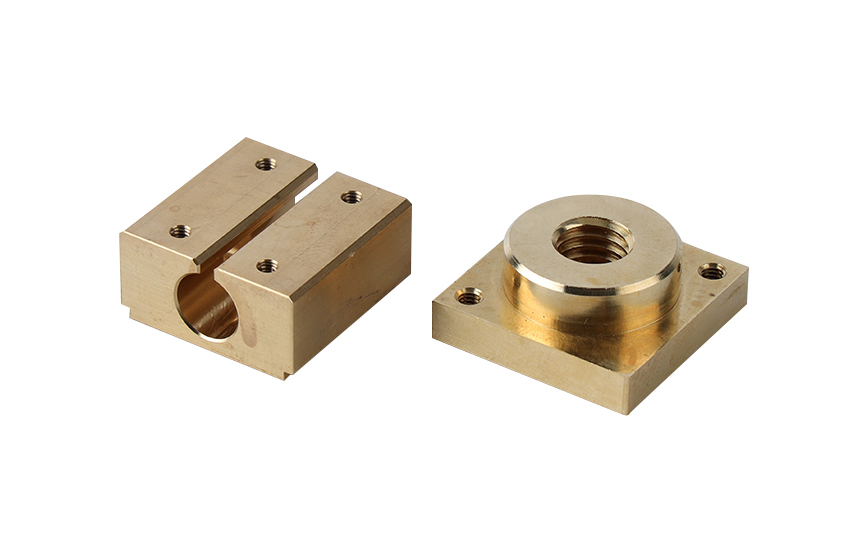

Brass is an alloy made of copper and zinc with strong wear resistance, low coefficient of friction, low melting point, good flexibility and high corrosion resistance,

making it ideal for thermal machinery and products.

Wide range of CNC brass materials:

Copper H62-Copper H96,Copper H177-2,Copper H177-2A,Copper HMn58-2

Surface treatment:

Chrome plating, brushed nickel, antique copper, imitation red copper

Various Brass CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Brass CNC machining applications:

Electrical appliances, electronics, lighting, architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, military supplies

Titanium is resistant to corrosion, chemicals, and extreme temperatures, and has an excellent strength-to-weight ratio. It is a typical ideal material for aerospace,

medical, military, chemical processing, marine industry, and extremely high-temperature applications.

A wide range of titanium processing:

TA1,TA2,TA5,TA22,TA23,TA24,TA31

Various titanium CNC machining processes:

CNC Aluminum Milling, CNC Aluminum Turning, CNC Aluminum Drilling

Titanium CNC machining applications:

Chemical, Petroleum Industry, Automotive Industry, Medical, Communication, Aerospace

Plastics are an integral part of our daily lives. It is known for its lightweight, high strength-to-weight ratio, electrical insulation,

low price, and suitability for mass production.

Wide range of CNC plastic materials:

● ABS ● PTFE

● Nylon ● PC

● POM ● HDPE

● PEEK ● PVC

● Acrylic ● PMMA

● PET ● PP

Start your project with a free quote

All information and uploads are secure and confidential.