Plastic

Injection Molding Service

Low-Volume and Mass Production in One Place

- Professional technical support

- Rapid manufacturing

- ISO 9001:2015 certificated

- Save 20% budget in average

Our experience in numbers

3000+

companies served

20000+

Unique parts produced

30+

Shipped country

12

Years In Service

Plastic, Liquid Silicone & Metal Injection Molding

Need to test the market with low-volume parts quickly? Or want to make a lot of production parts? Don’t miss our injection molding service! At Keyanng, we use aluminum molds to produce high-quality prototype molds with short turnaround times. Our customers can quickly test the manufacturability and functionality of their designs. We also offer plastic injection molding to meet your high volume production needs.

Whether you need rapid tooling, mass production tooling, or end-use plastic molding with tight tolerances, our experienced experts can provide cost-effective solutions at every stage.

Advantages of

Injection Molding with Keyanng

There are a large number of mold making companies. Why choose us as your mold and injection molding supplier?

- Strong Capability

Our experienced prototype injection molding services offer a complete list of injection molding processes, as well as over 100 materials and finishes to meet your custom injection molding needs.

- High efficiency

As an injection molding manufacturer in China, we provide affordable injection molding quotes within 1 working day. Additionally, rapid injection molding with no minimum order quantity makes it available for initial development.

- Reliable quality

Quick turn Injection molding with Keyanng is at ease. We provide free DFM feedback, certifications and production update through the process. You always get high quality custom molded plastic parts.

See why they chose

keyanng

Our Injection Molding Capability

At Keyanng, our experienced team produces the highest quality injection molded products. We use injection molding in conjunction with our rapid machining capabilities, allowing us to create detailed custom parts quickly and efficiently. Our injection molding technology enables us to use a variety of materials and finishes to meet the needs of any industry or application.

Here are some options you can choose from:

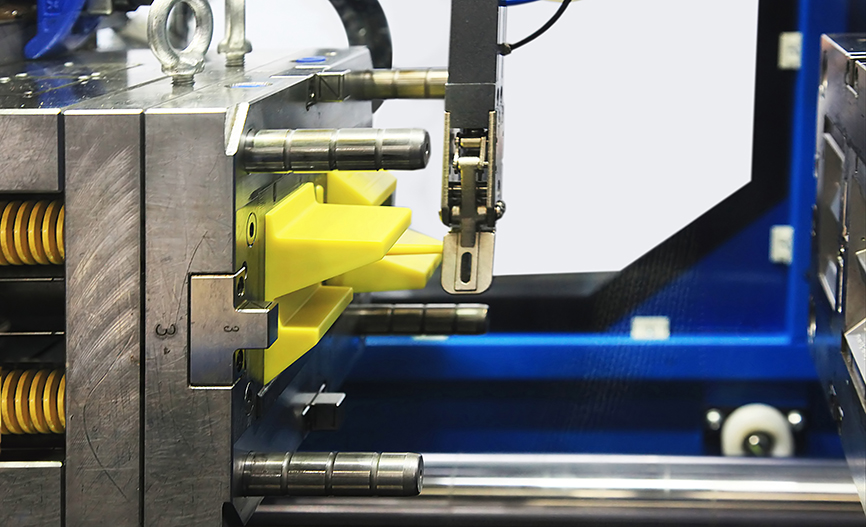

Plastic Injection Molding

The most popular process for plastics, thermoplastic injection molding is suitable for consumer products, automotive components, and everything in between.

Liquid Silicone Rubber Molding

Liquid silicone injection molding is ideal for creating detailed, temperature-resistant parts from thermosets liquid silicone, either alone or with overmolding.

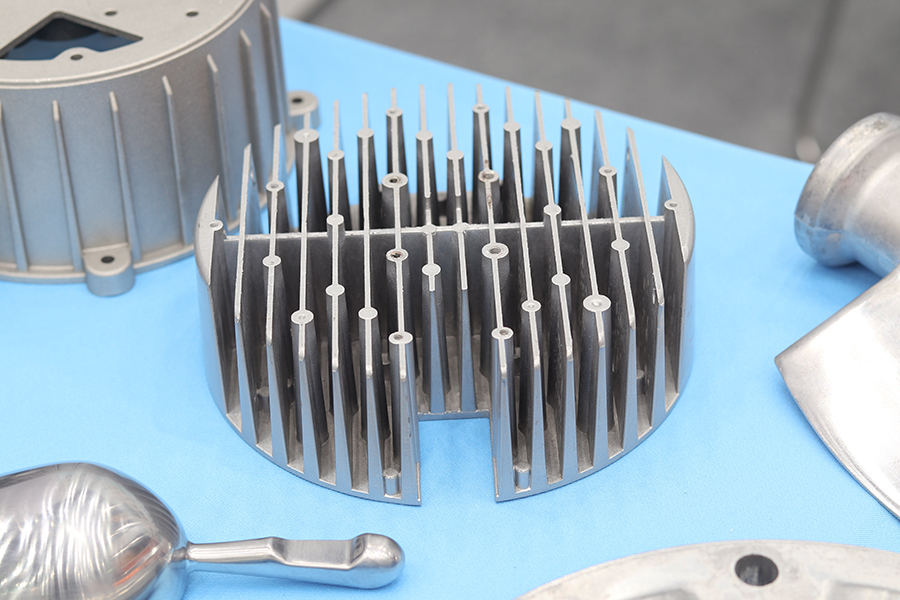

Metal Injection Molding

Suitable for small and detailed metal parts, metal injection molding is cost-effective in large volumes and wastes less material than CNC machining.

Injection Molding Services

Need to quickly test out the market with low-volume parts? Or want to create large quantities of production parts? Then you can’t go wrong with our injection molding services. At 3ERP, we produce high-quality prototype moldings from aluminum molds with quick turnaround times. Our customers can test out their designs for manufacturability and functionality, fast. We also offer plastic injection molding for your high-volume production needs.

Whether you need rapid tooling, mass production mold making or end-use plastic molding with tight tolerances, our team of experienced specialists can offer a cost-effective solution at each stage.

Overmolding

Overmolding uses injection molding to create a part from multiple materials. This process adds an injection-molded layer of material over an existing injection-molded workpiece. The overmolding process produces chemically bonded parts made using multiple materials.

The overmolding method is often cheaper and more effective than other manufacturing approaches that require creating and assembling component material parts separately. The process can also be used to build layered parts from scratch or to add a resistant outer layer to existing plastic parts and tools, providing a more rugged exterior. Toothbrushes consisting of a solid plastic body and rubberized grip are a common example of an overmolded product.

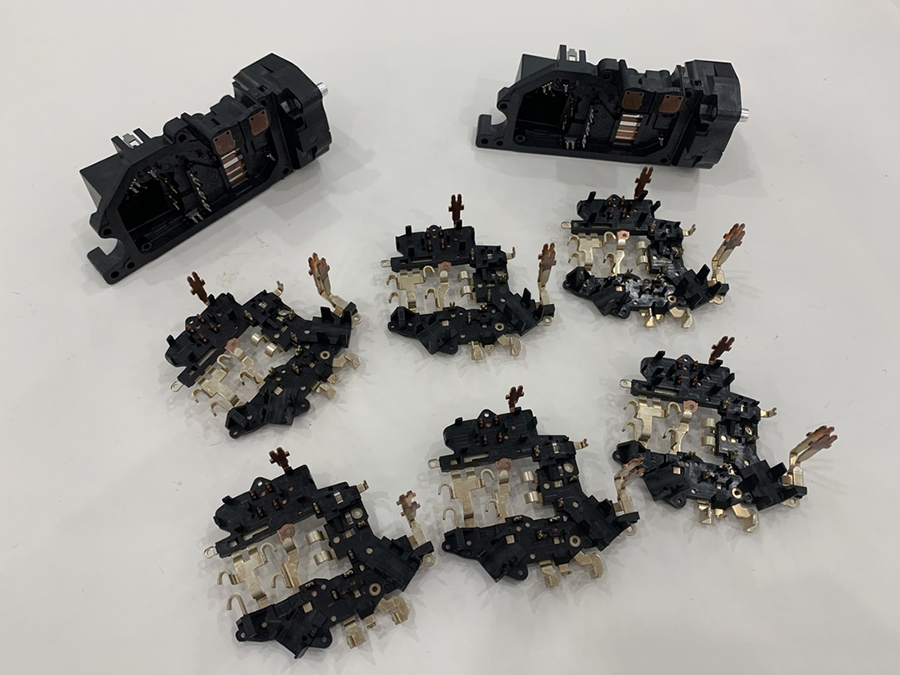

Insert Molding

Insert molding is similar to overmolding, but the substrate is not necessarily plastic and does not have to be produced via injection molding. For example, insert molding can be used to add a plastic coating to a pre-fabricated metal part.

Common parts made by insert molding include sharp handheld tools, such as scalpels, which consist of a metal blade partially housed within a plastic handle. Insert molding is also frequently used to create products that incorporate bushings, clips, and fasteners

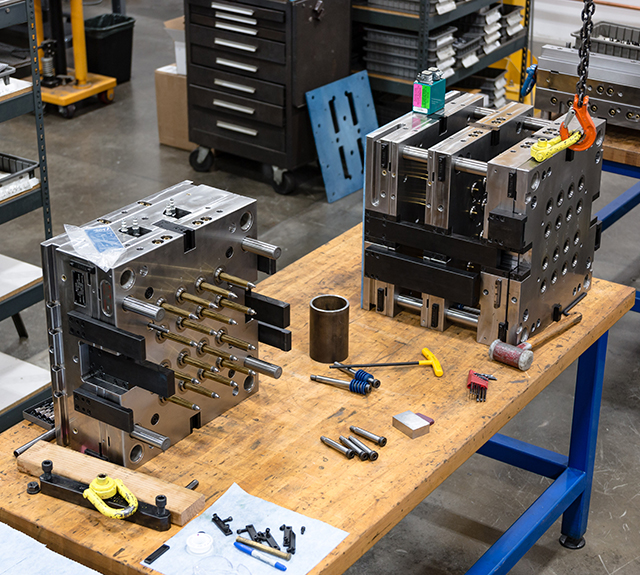

Mold Making Processes

We manufacture the molds in accordance with the final specifications before shipping them to the customer.

Materials

● Acetal polyoxymethylene (POM)

● Acrylonitrile butadiene styrene (ABS)

● Nylon 66 (PA66)

● Glass-filled, polyamide (PA-GF)

● High-density polyethylene (HDPE)

● Low-density polyethylene (LDPE)

● Polybutylene terephthalate (PBT)

● Polycarbonate (PC)

● Glass-filled polycarbonate (PC-GF)

● ABS polycarbonate (PC-ABS)

● Polyethylene terephthalate (PET)

● Polymethyl methacrylate (acrylic) (PMMA)

● Polyphenylene sulfide (PPS)

● Polypropylene (PP)

● Polystyrene (PS)

● Polystyrene + polyphenyl ethers (PS-PPE)

● Thermoplastic elastomer (TPE)

● Thermoplastic vulcanizates (TPV)

Finishing Options

● Polishing

● Pad printing

● Silk screening

● Custom color painting

● Laser finishing

● Heat staking

● Texture finishing

Advantages of Injection Molding

Injection molding is an excellent option for the large-scale production of plastic parts and components. After all, there’s a reason why so many high-tech companies use it for producing parts all around the world. But what makes injection molding so popular?

Well, here are some of its biggest advantages:

Efficiency

The mold injection process is highly efficient, allowing to produce large orders quickly.

Superior detail

The high pressure of injection ensures that the melted material reaches every crevice of the mold before curing. This enables design engineers to incorporate complex geometrics and intricate elements into their designs.

Affordability

Fast and efficient production ensures a low cost per part, while high production volumes produce further economies of scale. Aluminum, a cost-effective and readily available material, can be used for tools to control costs.

High-volume production

Injection molding with steel molds can facilitate high-volume production of parts into the millions.

High tensile strength

Injection-molded parts may be reinforced by adding fillers into the liquid resin, improving tensile strength.

Ready-to-go finish

With the proper treatment, injection-molded parts come out of the mold with a smooth finish that requires no further refinement.

Plastic Injection Molding FAQ

Injection molding can use almost any type of plastic that can also be combined together. This unmatched versatility is what makes injection molding so popular and suitable for some of the most demanding industries in the world. You can check out our selection of available materials and finishes on this page.

The plastic pellets are melted and are then inserted in liquid form into the mold tool, where it cools and takes the required shape. The process allows for high precision and tight tolerances because it can be replicated exactly each time.

Injection molding is one of the most affordable ways to manufacture large quantities of parts, especially for bigger production runs. Even though designing and creating the mold can take time, after that, the process becomes very affordable and efficient.

Before production can begin, we will first need to design the injection mold tool. How long this takes will depend on the complexity of your project, but the usual timeline can be as short as a week and as long as a couple of months.

Start your project with a free quote

All information and uploads are secure and confidential.