Rapid Prototyping Parts On Demand

Our rapid prototyping services enable companies to get the necessary feedback, revise, iterate and bring better products to market faster than ever before.

- 200+ material types

- Parts ship in 7 days

- Confidentiality Agreement

Rapid Prototyping Parts On Demand

Our rapid prototyping services enable companies to get the necessary feedback, revise, iterate and bring better products to market faster than ever before.

- 200+ material types

- Parts ship in 7 days

- Confidentiality Agreement

Our Rapid Prototyping Services

Rapid prototyping is a product development method that utilizes turnkey manufacturing techniques to rapidly produce multiple iterations of components for testing and evaluation. If you are looking for professional prototyping services to help realize your ideas and assist with product development, Keyanng is the best choice for you. We offer several rapid manufacturing processes that can be used to create prototypes quickly and cost-effectively.

Our Rapid Prototyping Services

Rapid prototyping is a product development method that utilizes turnkey manufacturing techniques to rapidly produce multiple iterations of components for testing and evaluation. If you are looking for professional prototyping services to help realize your ideas and assist with product development, Keyanng is the best choice for you. We offer several rapid manufacturing processes that can be used to create prototypes quickly and cost-effectively.

Rapid 3D Printing Processes

3D printing is the most common rapid prototyping process. The main advantages of using 3D printing are speed and affordability.

Our 3D printing rapid prototyping services are ideal for 3D printing plastics and metals, offering a wide range of material and finish options. These additive manufacturing techniques are sometimes used in production as well.

Our 3D printing services are Selective Laser Sintering (SLS), Stereolithography (SLA), Fused Deposition Modeling (FDM) and PolyJet.

Rapid 3D Printing Processes

3D printing is the most common rapid prototyping process. The main advantages of using 3D printing are speed and affordability.

Our 3D printing rapid prototyping services are ideal for 3D printing plastics and metals, offering a wide range of material and finish options. These additive manufacturing techniques are sometimes used in production as well.

Our 3D printing services are Selective Laser Sintering (SLS), Stereolithography (SLA), Fused Deposition Modeling (FDM) and PolyJet.

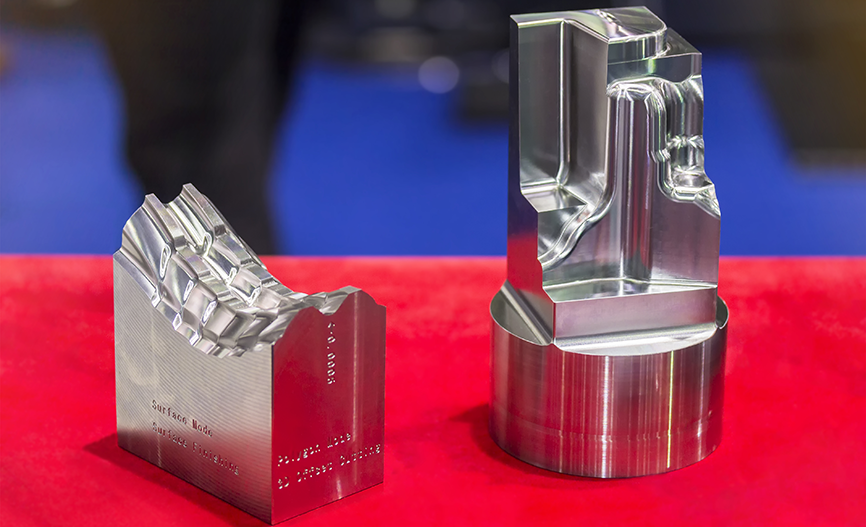

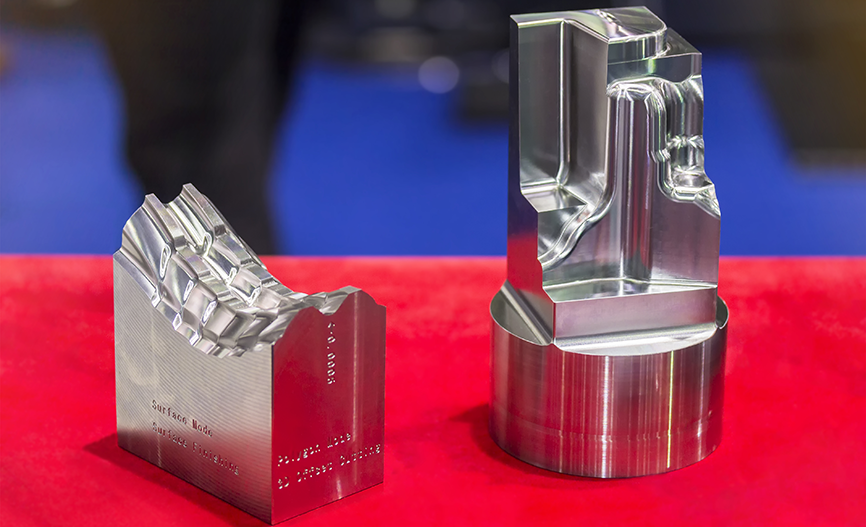

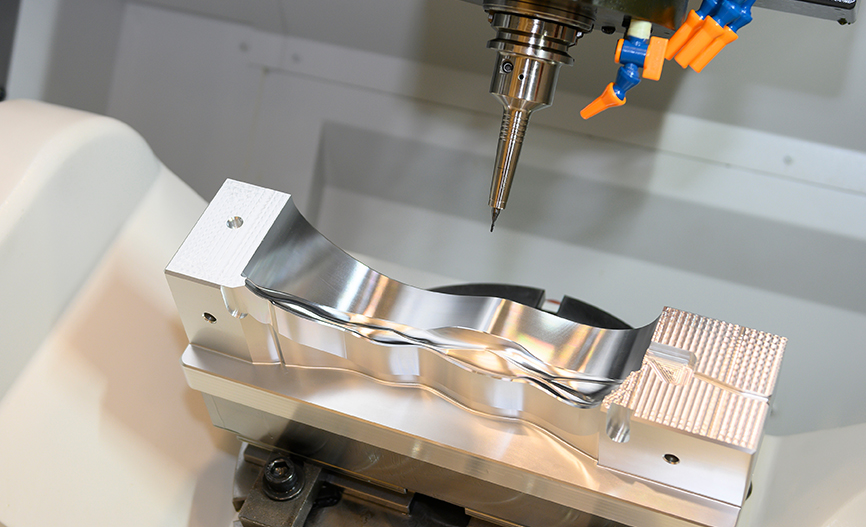

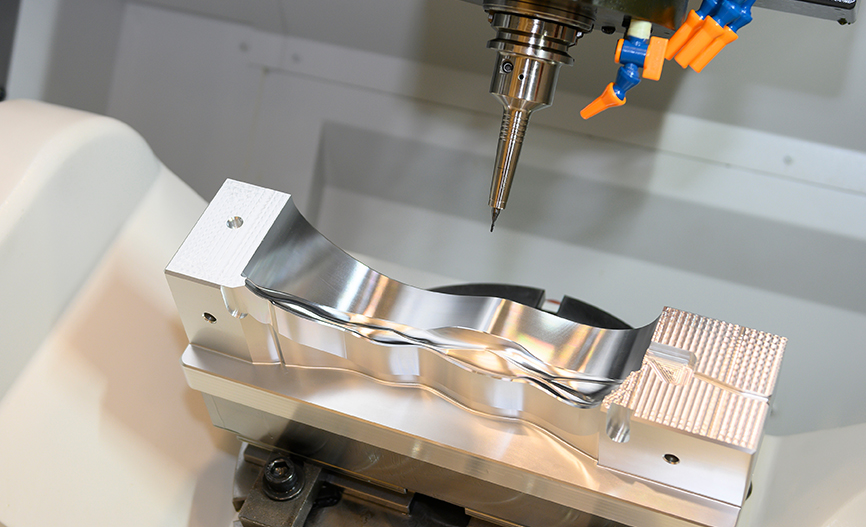

Rapid CNC Machining

Keyanng can process a wide variety of metals and plastics. Many CNC machined parts can be manufactured and shipped within a week. We offer a wide range of material and finishing options and combine CNC machining with other rapid prototyping processes.

CNC machining is one of the highest precision rapid prototyping techniques. Although the turnaround speed is not as good as 3D printing, the quality is still high, and the surface finish and part strength are generally superior.

Rapid CNC Machining

Keyanng can process a wide variety of metals and plastics. Many CNC machined parts can be manufactured and shipped within a week. We offer a wide range of material and finishing options and combine CNC machining with other rapid prototyping processes.

CNC machining is one of the highest precision rapid prototyping techniques. Although the turnaround speed is not as good as 3D printing, the quality is still high, and the surface finish and part strength are generally superior.

Rapid Sheet Metal Fabrication

Rapid sheet metal prototyping is a fast prototyping service that flips flat parts. Rapid sheet metal prototyping is often used for flat parts such as brackets and housings. It can accommodate various sizes, including extensive metal parts. Sheet metal is highly cost-effective when manufacturing large and relatively simple parts.

The lead time for fast sheet metal parts is comparable to fast CNC machined parts, usually around 7 days.

Rapid Sheet Metal Fabrication

Rapid sheet metal prototyping is a fast prototyping service that flips flat parts. Rapid sheet metal prototyping is often used for flat parts such as brackets and housings. It can accommodate various sizes, including extensive metal parts. Sheet metal is highly cost-effective when manufacturing large and relatively simple parts.

The lead time for fast sheet metal parts is comparable to fast CNC machined parts, usually around 7 days.

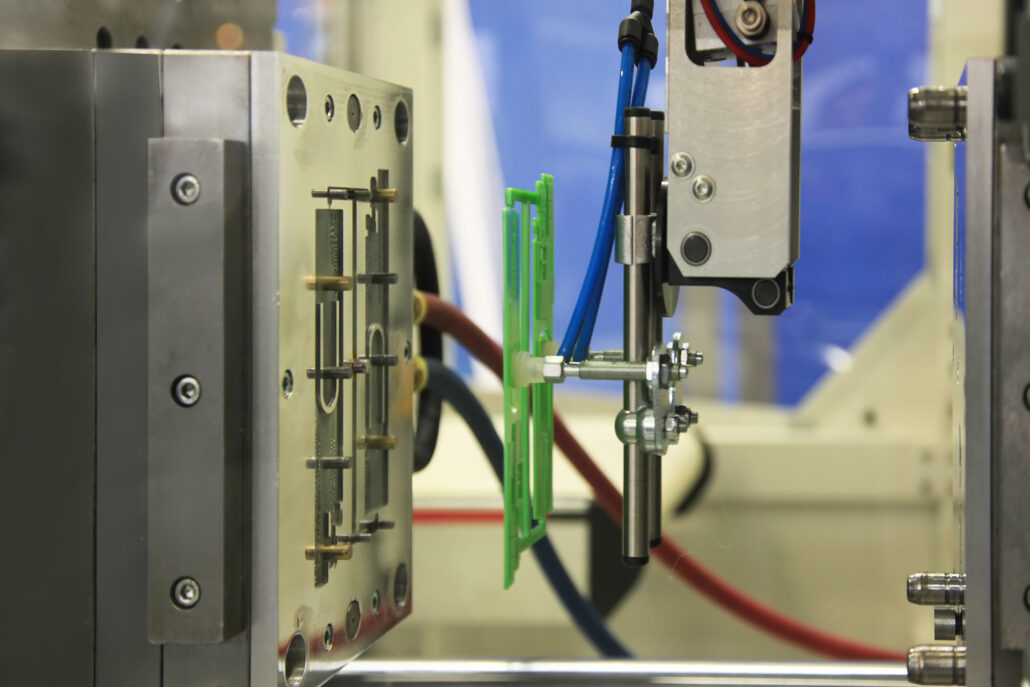

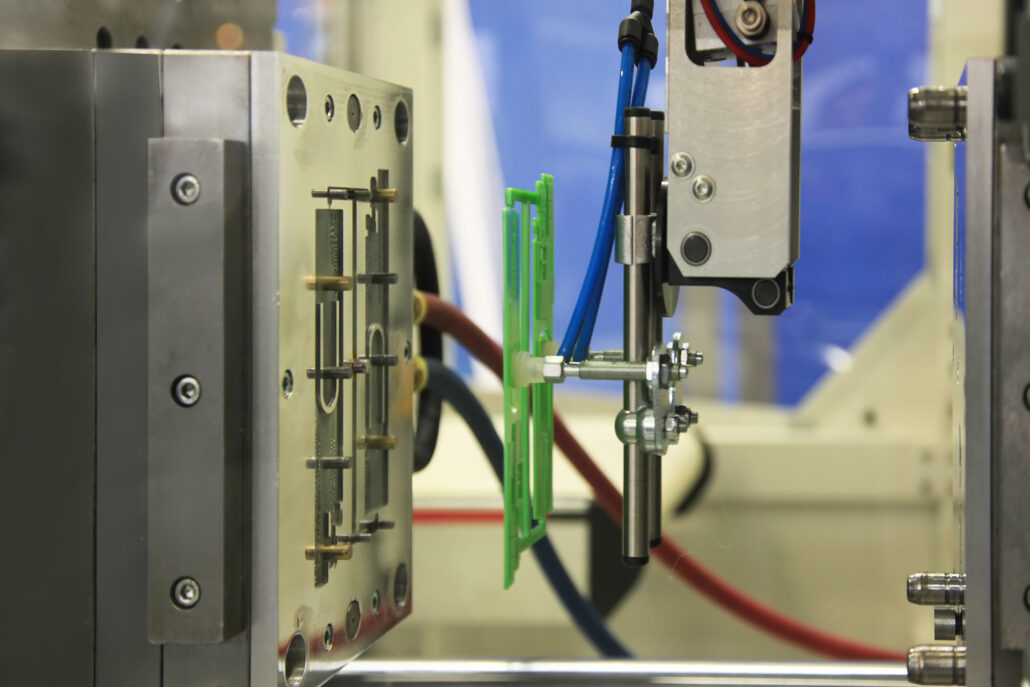

Rapid Injection Molding

Rapid sheet metal prototyping is a fast prototyping service that flips flat parts. Rapid sheet metal prototyping is often used for flat parts such as brackets and housings. It can accommodate various sizes, including extensive metal parts. Sheet metal is highly cost-effective when manufacturing large and relatively simple parts.

The lead time for fast sheet metal parts is comparable to fast CNC machined parts, usually around 7 days.

Rapid Injection Molding

Rapid sheet metal prototyping is a fast prototyping service that flips flat parts. Rapid sheet metal prototyping is often used for flat parts such as brackets and housings. It can accommodate various sizes, including extensive metal parts. Sheet metal is highly cost-effective when manufacturing large and relatively simple parts.

The lead time for fast sheet metal parts is comparable to fast CNC machined parts, usually around 7 days.

See why they chose

keyanng

Why choose our rapid prototyping services?

So many prototyping companies, why choose keyanng?

Competitive Pricing

We have established our own factory and technical team in China, enabling us to offer competitive prices that match any offer.

Rapid Turnaround

Our robust production capabilities enable your rapid prototyping projects to be completed within days.

No MOQ

We are very flexible with one-off prototypes and low-volume parts. No matter the size of your order, we can handle it.

Technical Support

Our team of designers and engineers can provide you with the most professional design and processing advice in the early stages of your product design.

Rich customization options

Choose from hundreds of possible combinations of materials, finishes, tolerances, markings and certifications for your order.

High Quality Guarantee

We strictly comply with ISO9001:2015 requirements and provide SGS, RoHS, material certification and full-scale reports according to your project needs.

Rapid Prototyping FAQ

It’s a model that uses technology to turn product ideas into reality.

The initial physical model is a prototype. Then you’ll design and refine it until you get the right final version. The faster you can produce and improve prototypes, the faster you can start getting to market.

When you have the following 3 needs, it is best to use our rapid prototyping services.

Concept prototypes: Demonstration prototypes (or look prototypes) are more mature prototypes that focus on the aspect of their appearance. It is used to convey the basic idea of a part.

Functional Prototype: Building a functional prototype behaves like an end-use part. This enables designers to perform any necessary mechanical tests on the prototype to ensure it functions correctly.

Pre-production prototype: A pre-production prototype or factory sample is the last prototype used before production. It is often used to validate the selected batch manufacturing process, ensuring that the manufactured part performs as expected.

Most rapid prototyping projects can be completed in a few days, and we offer fast global delivery. If you need an accurate lead time, please submit your project to get a free quote and lead time information at the same time.

Start your project with a free quote

All information and uploads are secure and confidential.