Cutting tools include tools, abrasives, and abrasives to remove excess material from a blank or workpiece to obtain a designed geometry.

The following is a brief introduction to the commonly used cutting tools of CNC machine tools.

Commonly used cutting tools for CNC machine tools include milling cutters, drills, taps, reamers, turning tools, hobs, etc.

- Milling cutter

Cutting tools commonly used in machining centers and milling machines, the most representative of which are end mills known as universal tools, can efficiently cut the planes, sides, grooves, and slits of workpieces.

- Drill bit

It is a cutting tool for drilling, commonly used in machining centers and drilling machines. According to the diameter and depth of the hole, a variety of drills are subdivided, such as oil hole drills that can improve the efficiency of chip discharge and long gun drills suitable for deep holes.

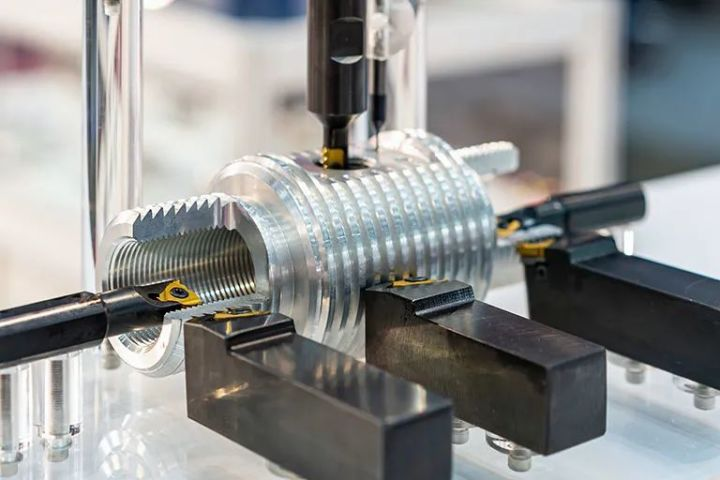

- Tap

A cutting tool for cutting threads (internal threads), tapping a threaded hole with a tap is called “tapping,” and it is an indispensable tool for machining mechanical parts with many lines.

- Reamer

It is a tool used to finish the hole’s inner diameter and surface roughness. The parts with high precision, such as automobile engine parts and aircraft parts, often use the reamer to repair the hole to ensure the accuracy of the spot.

- turning tool

A cutting tool with a chip edge on the top and one of the most widely used cutting tools today, commonly used on lathes and turning centers. It cuts into the rotating workpiece to scrape the metal surface.

- Hob

Gear hobbing machines, gear cutting machines, and other special tools used in gear processing machinery are mainly used to process gears or workpieces with teeth.

What materials are used to make tools?

Materials used to manufacture cutting tools are tool steel, high-speed steel, cemented carbide, and diamond.

“Hardness” and “toughness” are two critical indicators of tools, which vary from material to material, and are generally selected according to the cutting scene and working conditions.

Will the tool be coated?

The coating is an indispensable surface treatment technology for tools. By applying a thin film to the tool’s surface, the tool material’s weakness is compensated. A high-quality coating can improve machining quality and increase tool life.