Welcome to Keyanng's Blog Center

We are happy to share the information, skills and experience we have learned over the years in the non-standard parts manufacturing industry.

How do you choose the right CNC machining service provider in China?

When you need CNC machined parts, you don’t have to invest the time and money to build your CNC production shop. Outsourcing to a CNC machining company would be a good choice. This article will introduce outsourcing CNC machining and teach you how to choose a suitable CNC machining service provider in China.

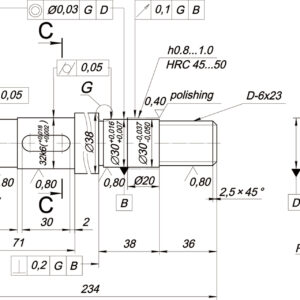

Why is 2D CAD drawing still important when sourcing parts?

In our experience, customers who provide 2D drawings and 3D part files experience fewer design errors, manufacture parts faster, and are more satisfied with the parts they receive.

Machining allowances in CNC machining – everything you need to know

CNC machining allowance is the reserved machining amount to ensure the final machining surface quality and geometric tolerance. Sometimes there is a heat treatment process in the middle to release the stress, and the parts will be deformed at this time, so enough allowance is reserved to prevent the size from being in place after deformation.

What are the commonly used cutting tools for CNC machining?

Cutting tools include tools, abrasives, and abrasives to remove excess material from a blank or workpiece to obtain a designed geometry.

The following is a brief introduction to the commonly used cutting tools of CNC machine tools.

Common problems and advantages and disadvantages of sheet metal stamping parts

The sheet metal stamping process transforms by stamping hot or cold-rolled steel sheets to create the shape required for your part. This technique allows many parts to be produced simultaneously, but it can also result in about 15% of the raw material being scrap. When working with sheet metal stamping, three types of dies are used – cutting, punching, and bending.

Material Requirements and Design Considerations for Sheet Metal Fabricated Housing Parts

Sheet metal processing is closely related to our lives, and almost all manufacturing industries are inseparable from sheet metal processing. Sheet metal shell processing products that meet these material requirements can better meet the needs of various sheet metal processing to produce high-quality sheet metal shell parts.