How do you choose the right CNC machining service provider in China?

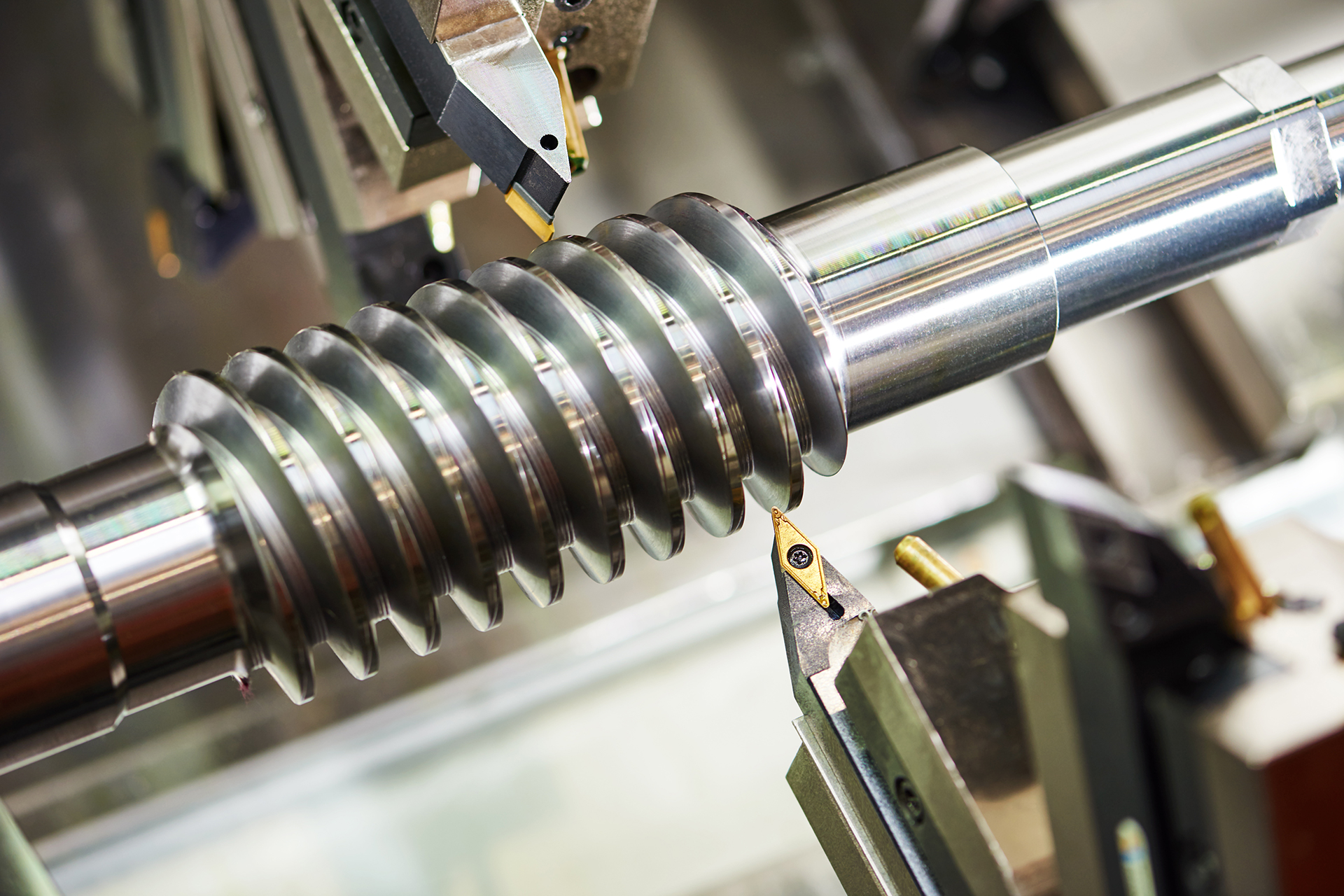

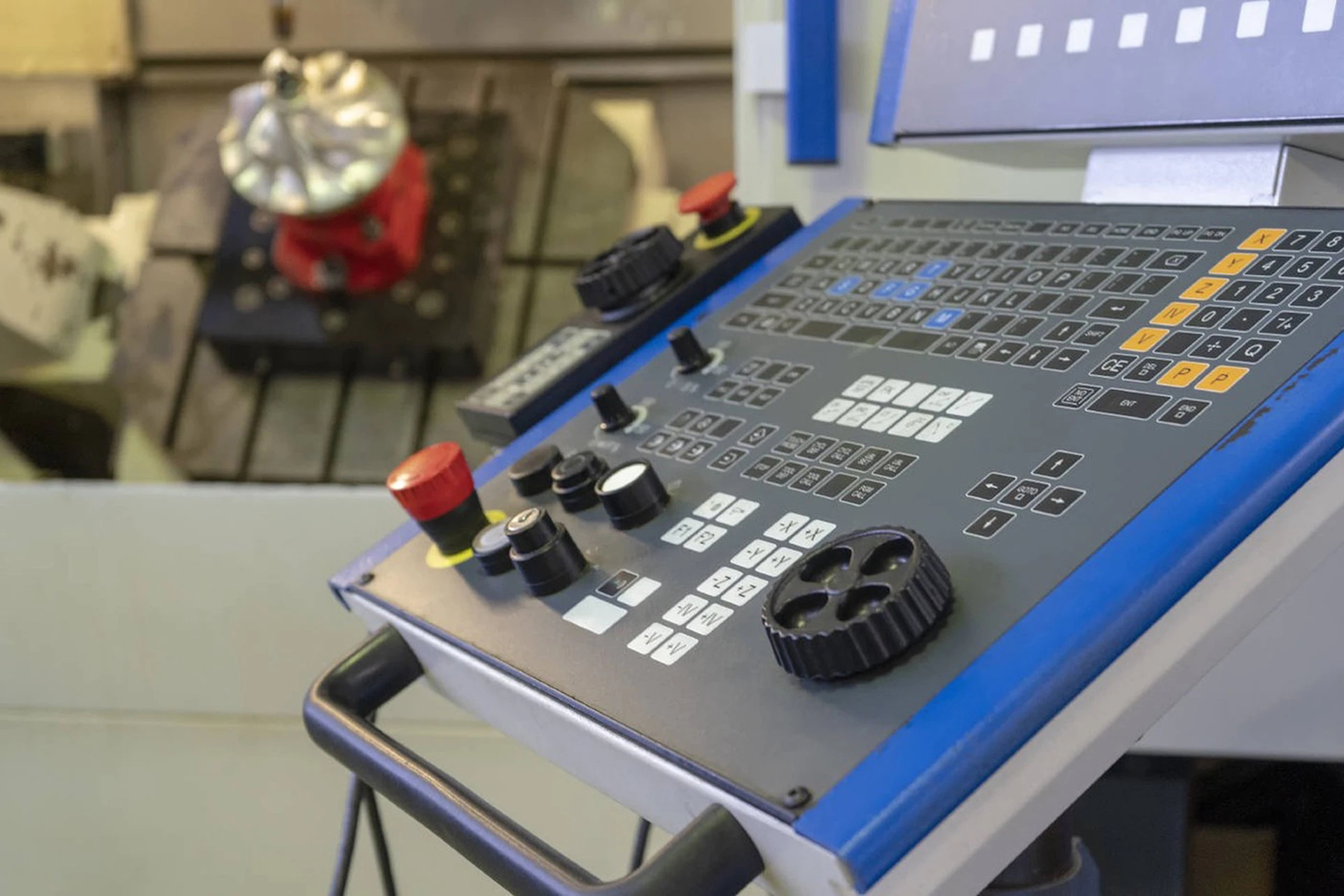

When you need CNC machined parts, you don’t have to invest the time and money to build your CNC production shop. Outsourcing to a CNC machining company would be a good choice. This article will introduce outsourcing CNC machining and teach you how to choose a suitable CNC machining service provider in China.